Explore Automation in Chemical Manufacturing

10-08-2025 140

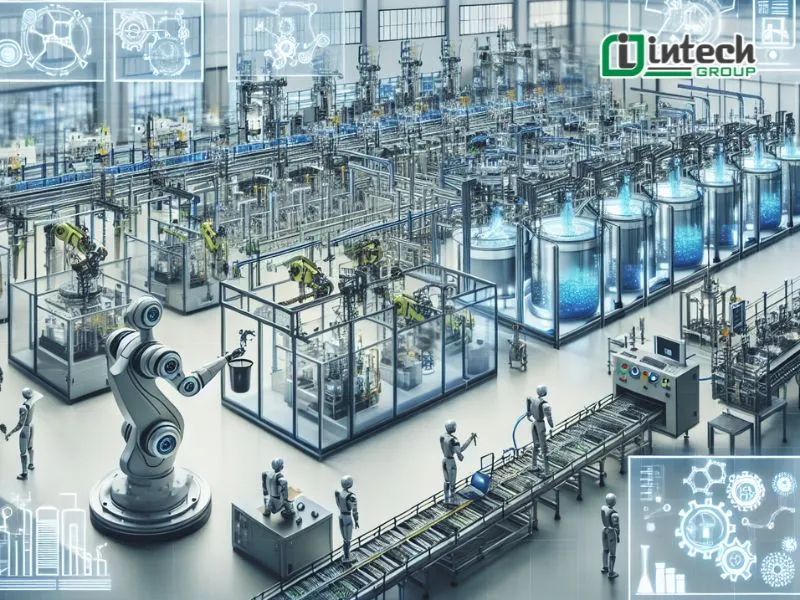

Faced with pressure on efficiency, competition and sustainable development, the application of automation in chemical production is not only a trend but has become an inevitable need. Automation helps businesses optimize operations, reduce costs, increase productivity and ensure safety in harsh working environments.

Mục lục

The chemical manufacturing industry plays a key role in many economic sectors such as agriculture, medicine, industry and daily life. However, this is also an industry that requires complex production processes, has many potential risks and requires strict control of safety and quality.

What is automation in chemical production?

Automation in chemical production is the process of applying control, monitoring and automatic operation technologies to perform production stages with little or no manual intervention from humans.

In the chemical manufacturing environment, automation includes the use of programmable control systems (such as PLC, DCS), sensors, measuring devices and management software to monitor and adjust important parameters such as temperature, pressure, flow, chemical concentration, etc. to ensure the process is stable, accurate and safe.

The application of automation not only helps optimize production efficiency but also contributes to improving product quality, minimizing risks and operating costs.

Benefits of automation in chemical production

The application of automation in chemical production brings many practical benefits to businesses, especially in the context of competition and increasing requirements for safety and quality. Specifically, the outstanding benefits include:

- Increasing productivity, reducing costs: The automation system helps optimize operating time, minimize production errors and save labor.

- Ensuring consistent product quality: Technical parameters are precisely and stably controlled, helping output products continuously meet standards.

- Enhancing labor safety: Automation minimizes human exposure to toxic chemicals or hazardous environments.

- Reducing environmental impact through strict control: Continuous monitoring and adjustment helps minimize emissions, wastewater and substandard waste.

- Increased competitiveness and production flexibility: Enterprises can easily adjust capacity, diversify products and quickly adapt to market demand.

These benefits not only help improve operational efficiency but also play a strategic role in the sustainable development of the chemical industry.

Automation technologies in chemical production

The following is an analysis of the main automation technologies used in chemical production:

- Automatic control systems (DCS, PLC, SCADA)

This is the core control platform in chemical plants. These systems allow for close monitoring and control of reaction processes, mixing, temperature adjustment, pressure and other technical parameters in real time. Thanks to that, the production process is stable, accurate and has fewer errors.

- Distributed control systems (DCS - Distributed Control System) are designed to manage complex production processes with many variables. DCS divides the control function into many small parts, linked together through a communication network, helping to increase reliability and reduce risks when a part of the system fails. Common applications of DCS appear in chemical plants, oil refineries and power plants, where continuous and stable control is required.

- Programmable Logic Controller (PLC) is an industrial electronic device designed to perform automatic control functions, especially in harsh industrial environments. PLCs are resistant to high temperatures, humidity, vibration and electromagnetic interference. They are programmed to perform specific tasks such as controlling assembly lines, packaging machines and batch manufacturing processes.

- SCADA (Supervisory Control and Data Acquisition) systems focus on monitoring and collecting data from various equipment and production processes. SCADA provides an intuitive human-machine interface, allowing operators to monitor the entire system from a central location. Common applications of SCADA include the management of electrical, water, gas, and complex logistics systems.

- Sensors and measuring devices

Sensors and measuring devices are the "senses" of automation systems, providing real-time information about the status of production processes and the environment.

Industrial sensors include a wide variety of sensors such as temperature, pressure, flow, liquid level, pH, humidity, and chemical composition sensors. These sensors continuously monitor critical parameters and send data to the central control system. Today's advanced sensor technology is capable of self-calibration and self-diagnosis, alerting when maintenance is required.

High-precision measuring systems such as laser meters, computer vision systems, and optical measuring devices ensure that products meet strict quality standards. These systems can detect the smallest defects that cannot be observed with the naked eye.

- Industrial Robots

- Industrial arm robots can perform a variety of functions such as welding, assembling, packaging, and palletizing. These robots are often equipped with specialized end effectors depending on the job requirements. For example, in the automotive industry, arm robots are widely used to weld car frames and assemble parts with millimeter precision.

- AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot) are mobile robots designed to transport raw materials and products in factories. While AGV usually moves along fixed paths, AMR is capable of mapping the environment and autonomously navigating, intelligently avoiding obstacles.

- Cobots (Collaborative Robots) are a new generation of robots designed to work safely with humans. Unlike traditional industrial robots that need to be isolated, cobots can work in the same workspace as humans, supporting tasks that require human dexterity and flexibility combined with the strength and precision of machines.

In stages such as packaging, shipping or product quality inspection, industrial robots are used to increase speed, reduce labor costs and limit the risk of exposure to hazardous chemicals. The high precision and performance of robots help ensure that logistics and product inspection processes meet standards.

- Artificial Intelligence (AI) and Machine Learning

AI and machine learning are revolutionizing automation, enabling systems to not only perform pre-programmed tasks but also learn, adapt and optimize processes.

Machine learning systems for predictive maintenance use historical and real-time data to predict when equipment is likely to fail. By detecting unusual patterns in sensor data, the system can warn of potential failures in advance, helping to minimize unplanned downtime and optimize maintenance schedules.

Computer vision combines cameras and AI algorithms to inspect product quality with speed and accuracy that surpasses humans. These systems can detect small defects such as cracks, dents, or uneven colors on high-speed production lines.

- Manufacturing Management Systems (MES, ERP)

These systems help integrate the entire manufacturing process with the supply chain, from raw materials to finished products. Thanks to MES and ERP, businesses can track progress, control inventory, manage quality, and make timely decisions based on real-time data.

Manufacturing Execution Systems (MES) monitor and manage the manufacturing process from order to finished product. MES provides real-time information on production progress, product quality, equipment performance, and many other factors. The system plays an important role in optimizing production schedules, minimizing downtime, and ensuring products meet quality standards.

Enterprise Resource Planning (ERP) integrates all aspects of a business, from manufacturing to finance, human resources, and supply chain. ERP helps synchronize information between different departments, ensuring data consistency and supporting informed decision making.

Challenges in automating heavy industry

In the heavy industry sector, where large scale, high complexity, and strict requirements make the automation process not only difficult, but also faces many great challenges, both technologically and humanly.

- High initial investment costs

This is a major barrier for many businesses in the heavy industry. Deploying automated systems such as industrial robots, centralized control systems (DCS, SCADA), sensors, and production management software requires a significant amount of capital. In addition, the cost of maintenance, upgrading, and training personnel to operate these systems is also a factor that businesses must consider carefully.

- Difficulty in integrating new technology into old systems:

Most of today's heavy industrial plants were built decades ago, with outdated infrastructure and equipment. Connecting traditional systems with modern technologies such as IoT, AI, or Big Data requires deep technical intervention, sometimes leading to production disruptions or incurring large costs for synchronization.

- Lack of highly skilled human resources is also a significant challenge.

Operating, monitoring, and maintaining automated systems requires a team of engineers and technology experts with specialized skills. However, this human resource is not only scarce but also requires a long time to train and continuously update knowledge according to the rapid development of technology.

- Cyber security issues:

When production systems are connected via the Internet and digital platforms, the risk of cyber attacks or data leaks increases. In heavy industrial environments, where a technical failure can cause serious damage to assets and worker safety, securing automation systems is vital.

Automation solutions in chemical production by Intech Group

As one of the pioneers in the field of technology and automation, Intech Group has researched and deployed many comprehensive solutions to optimize the chemical production process. Notable solutions include: automated warehouse systems, industrial robots, AGV autonomous robots and specialized conveyor systems.

- Automated warehouse system (AS/RS)

Intech Group develops an automated warehouse system (Automatic Storage and Retrieval System - AS/RS) with the ability to store and manage goods intelligently. In the chemical industry, where there are many materials and raw materials that need to be stored according to strict standards, automated warehouses help optimize storage space, control inventory in real time and minimize risks due to manual operations.

Integrating modern management software also helps businesses easily retrieve shipment information, expiry dates and control quality along the chain.

- Industrial robots

Industrial robots provided by Intech Group are applied in many stages such as: packaging, labeling, loading and unloading packaging, checking product appearance, etc.

With the ability to work continuously, accurately and stably in toxic environments, robots not only help increase productivity but also ensure safety for workers. In particular, in the production environment of flammable and explosive chemicals or containing dangerous chemicals, replacing humans with robots is the optimal solution in terms of safety.

- AGV (Automated Guided Vehicle) Robot

Application of AGV autonomous robots in transporting raw materials and finished products between workshops, warehouses and production areas. AGV helps reduce dependence on forklifts or workers, limit collisions and breakages, especially in transporting hazardous chemicals.

Thanks to the intelligent navigation system, AGV can automatically avoid obstacles, plan optimal routes and integrate with the overall production system for smooth, continuous operation.

- Automatic conveyor and transportation systems

Intech Group designs and installs automatic conveyor systems to transport chemical raw materials and finished products through production stages. These conveyors are integrated with intelligent control technology, ensuring continuous, accurate and safe operation in hazardous chemical environments.

The conveyor system can be customized as required, for example, for packing boxes, or transporting to warehouses, forming a fully automated closed chain.

- Automated packaging system:

Automated packaging solutions, including strapping machines, carton packing machines, pallet shrink wrapping machines, etc. These systems are designed to handle liquid, powder or granular chemical products, ensuring packaging quality and minimizing errors.

An automated packaging quality inspection system is also integrated to detect packaging errors, ensuring that products meet standards before leaving the warehouse.

At Intech Group, with a team of experienced engineers, advanced technology and professional support services, we are committed to accompanying businesses on the journey of digital transformation and automation, towards sustainable development in the future. Contact Intech Group today for detailed advice and quotes:

- Hotline: 0966 966 032

- Address: Lot 6, Lai Xa Industrial Park, Tay Tuu Ward, Hanoi City