Speed up production with robotic loading stations for the food and beverage industry

10-08-2025 62

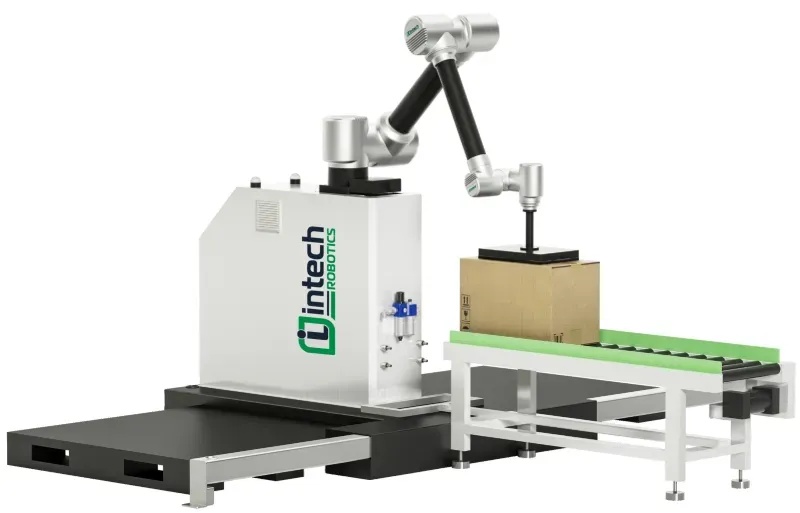

The robotic pick and place station is a comprehensive solution for the food and beverage industry, combining high performance, safety and economy.

Mục lục

In the food and beverage industry, where production speed, precision and hygiene are decisive factors, challenges are always present. Manual loading and unloading of goods is not only time-consuming and labor-intensive, but also poses many risks of injury and hygiene safety.

Robotic loading and unloading stations are a comprehensive solution, a breakthrough step, helping businesses in this industry free people from heavy work, towards a more modern and efficient production process.

Robotic loading and unloading stations are a comprehensive solution, a breakthrough step, helping businesses in this industry free people from heavy work, towards a more modern and efficient production process.

Introduction to robot loading and unloading stations

Robot loading and unloading stations are an automation system that integrates collaborative robots (cobots) with components such as flexible robot arms, multi-purpose grippers (vacuum, servo or pneumatic grippers), smart conveyors, vision sensors and central controllers. This system is designed to perform the tasks of lifting, moving and arranging goods onto pallets or fixed positions accurately, especially suitable for light to medium goods such as cartons, bottles, cans or food packages.

In the food and beverage industry, the robot station not only replaces manual labor but also ensures high hygiene thanks to its easy-to-disinfect design and reduced human contact.

The basic structure of the robot loading and unloading station includes:

- Main robot: Arm with 6-7 degrees of freedom, stacking speed of 8-10 boxes/minute or up to 100 times/minute depending on the load (10-50kg).

- Sensor system: 3D vision to identify products, force sensor to avoid collision.

- Specialized gripper: Flexible to handle a variety of shapes, from glass bottles to paper boxes.

- Controller: Intuitive interface, supports fast programming (change specifications in 5 minutes) and integrates with the production management system (MES).

- Safety system: Emergency stop sensor, protective fence, ensuring safe working alongside humans.

- Simple but effective operating principle: Sensors identify goods on the conveyor, controller calculates trajectory, robot performs loading and unloading and continuous safety monitoring system.

Why is the robot loading station the ideal solution for the food and beverage industry?

- Increase working efficiency 24/7: Robots can work continuously, non-stop, meeting all requirements for large output, especially during peak seasons. This ensures the production process is always stable and efficient.

- Ensure food hygiene and safety: With stainless steel materials, easy to clean, the robot loading station meets strict industry standards. Minimizing manual contact also helps prevent cross-contamination and protect product quality.

- Improve accuracy: Robots stack goods neatly and securely, minimizing damage during transportation and storage. This accuracy also helps optimize warehouse space, bringing high economic efficiency.

- Minimize risks and ensure safety: Robots replace humans in heavy, repetitive and dangerous jobs. This not only frees up labor but also significantly reduces the risk of injury to workers, creating a safer working environment.

Application of robot loading and unloading stations in the food and beverage industry

Robot loading and unloading stations are widely used and highly effective in many fields:

- Beverage industry: Automatically load and unload beer crates, soft drinks, and mineral water bottles onto pallets, helping to increase production speed and reduce labor.

- Dairy and processing industry: Robots can operate in cold storage environments, placing cartons of fresh milk and yogurt in position accurately and efficiently.

- Packaged food: Automate the process of loading and unloading rice bags, instant noodle boxes, candy boxes, etc. onto pallets, ensuring product uniformity and safety.

Challenges of robot loading and unloading stations in the food and beverage industry

In the food and beverage industry, the application of robot loading and unloading stations brings many benefits, but also faces many challenges.

- High initial investment costs: Equipping a robot system, conveyor belts and control software requires a large initial investment, which can be a barrier for small and medium-sized enterprises.

- Technical requirements: Operating and maintaining robots requires a team of qualified engineers, while this human resource is still limited in Vietnam.

- Product Diversity: The food industry has a wide range of products with different sizes and shapes, requiring robots to be highly flexible to change grippers or work programs.

- Changing habits: Some businesses are still familiar with traditional processes, are afraid of change and have not yet realized the long-term effectiveness of automation.

Intech Group offers specialized Robotic Picking and Unloading solutions for the food and beverage industry

The food and beverage industry is facing major challenges in terms of speed, safety and labor costs. It's time for your business to need a breakthrough solution.

Intech Group is proud to introduce a specialized robot loading station solution for the food and beverage industry. Our system not only replaces labor, minimizes risks but also ensures that the production process is fast, accurate and especially strictly complies with hygiene standards.

With Intech Group's robot loading station, you will:

- Increase productivity many times over, especially during peak seasons.

- Save labor costs and optimize storage space.

- Improve product quality and ensure absolute safety.

Let Intech Group help you modernize your factory, enhance competitiveness and develop sustainably in the 4.0 era. Contact us today for advice on the most suitable solution!

- Hotline: 0966 966 032

- Address: Lot 6, Lai Xa Industrial Park, Tay Tuu Ward, Hanoi City