In any industry, transporting different materials or finished products is an important task, although it is not an easy task. That is why industries are turning to chain conveyors that allow them to move different types of goods and materials with ease.

What is a chain conveyor?

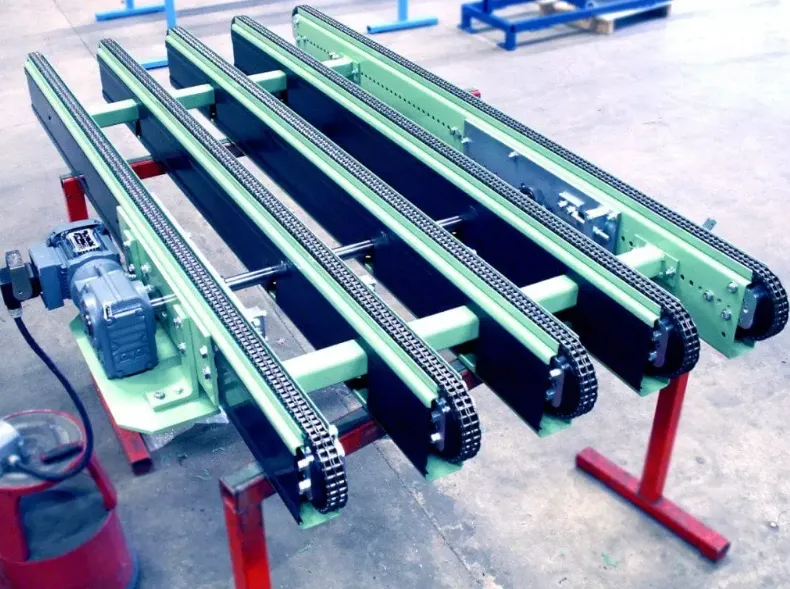

A chain conveyor is a type of conveyor used to move goods along a production line. The conveyor consists of continuously arranged chains, with the help of a motor, so it is used to transport heavy-duty materials.

The conveyor can have double chains or single chains depending on the requirements of the industry. Regardless of the type of system being used, the mechanism always remains the same. The mechanism works in a way that when the load is positioned on the chain then due to friction, the chain starts moving forward and at the same time pulls the load forward with the same method.

Conveyors use a plastic or stainless steel chain to transmit force and push materials. They are suitable for many items that are not normally transported on roller conveyors.

Chain conveyor structure: Chain conveyors include the following main parts:

- Chain conveyor belt: Conveyor chains include 2 types of stainless steel, plastic and different specifications depending on the application to use the appropriate type of chain conveyor belt.

- Plastic chain conveyor: quite light weight, simple and sturdy structure, high aesthetics can meet all terrains.

- Stainless steel chain conveyor: made of stainless steel, resistant to high abrasion, high durability, so it is used in harsh environments.

- Drive reduction motor: This is a type of reduction motor with capacity of 0.2, 0.4, 0.75, 1.5, and 2.2KW.

- Chain conveyor frame: Made of stainless steel, steel or aluminum profile.

- The electrical cabinet includes electrical equipment such as speed control inverters, relays, contactors, switches, timers, etc.

- There is a lighting system, pneumatic lines, etc. if required for use.

- There are support arms, support bars and product barriers.

- The conveyor system runs smoothly and stably.

- Size: Length from 500m to 50,000mm, width from 50mm to 1500mm.

Application of chain conveyors in industry

Chain conveyors are used to move products down assembly lines or around manufacturing facilities or warehouses. Chain conveyors are mainly used to transport heavy unit loads, such as pallets, mesh boxes and industrial containers, and any product with a solid bottom surface. Many industrial sectors use chain conveyor technology in their production lines.

- The automotive industry often uses chain conveyor systems to transport car parts through paint plants.

- Chain conveyors are also widely used in the distribution industry

- Applications are numerous in the food industry, especially in the production of beverages and agricultural products.

- Applications in the electronics assembly industry such as TVs, refrigerators, air conditioners, sewing machines, electric bicycles, motorbikes, cars, etc.

Benefits of using chain conveyors in the transport of goods

- Sturdy conveyor structure and stable chains for transporting heavy loads

- Infinitely expandable due to modular construction

- Durable and low maintenance thanks to high-quality components and smart maintenance options

- Simple personalization and adaptation, even under adverse conditions (complex transported goods, difficult environments, etc.)

- Using low-wear, high-strength plastic and stainless steel chains

- Chain conveyors take up minimal space while optimizing material handling capabilities.

- The conveyor also reduces average power consumption, increasing your operating profits.

- Chain conveyors are convenient to use at a reasonable cost

- High reliability in the transmission process

- Easy to control products during movement, helping to increase production capacity

- Faster transmission speed and reduce risks compared to manual labor

Classification of chain conveyors

Chain conveyors are available in many different types, installed according to usage requirements. They are extremely durable and can withstand heavy loads. Conveyors can be installed in different lengths and widths depending on the type of load and weight.

- Double chain conveyors: Transport horizontal goods and transport difficult-to-transport goods on roller conveyors.

- Three-wire chain conveyors: Transport whole pallets and goods that are difficult to transport on roller conveyors.

- Five-wire chain conveyors: With side-mounted drives used to transport whole pallets and goods that are difficult to transport on roller conveyors.

- Scraper chain conveyor: Commonly used in the mining industry, often designed with a hopper

- Hanging chain conveyor: Installed high in factories producing automobiles, garments, electronics, etc.

- Plate chain conveyor: Structured by plastic or stainless steel chains, capable of carrying heavy loads

Effective Industrial Chain Conveyor Maintenance Guide

Keeping your conveyor system running efficiently is key to maximizing your Return on Investment (ROI), which is why maintenance is so important.

When chains are maintained, they deliver optimal performance. However, if they are neglected, the daily wear and tear of metal on metal will lead to damage such as chain stretch or loss of tensile strength. The best way to avoid these problems and optimize your chain and production performance is to perform regular maintenance. The most important factors are proper lubrication and timely replacement of worn parts.

Here are our tips for extending the life of your chain.

- Lubrication

Lubrication is so important to function that manufacturers often dip chains in a solid lubricant at the factory. This grease provides a preliminary protective lubrication before shipping to the buyer.

Lubricants must be applied properly to be effective in protecting the chain. You can’t just brush or spray it onto the outside surface. The chain consists of a series of joints and bearings, all of which require lubrication to ensure longevity. Lubricants must be applied thoroughly to all areas, including the inner and outer plates, and the bearings.

- Ensure Quality Equipment

When it comes to purchasing equipment that will become the backbone of your processing, don’t settle for less quality for a lower upfront cost. Compromising on quality will only hurt you in the long run when parts fail and need to be replaced.

- Schedule Chain Conveyor Maintenance

Quality equipment and lubrication are just one aspect of maintaining the integrity and longevity of your chain conveyor system. You should also keep a basic maintenance schedule, along with a log, to ensure your operations continue to run smoothly.

Ensure that any personnel performing maintenance checks are trained and familiar with their duties. They will also need to record the maintenance and any necessary data appropriately in a logbook.

These are the basic maintenance requirements for chain conveyor systems. We recommend that you check your owner’s manual for any specific or additional requirements for your equipment:

Daily Maintenance:

- Check the conveyor chain daily for signs of wear and stretch.

- Remove any debris that may have accumulated in the chain.

- Check the drive system tensioner and lubricate the drive sprockets as required.

Weekly Maintenance:

- All chains, sprockets and components should be inspected and lubricated as required.

- Check that the drive system tensioner is within acceptable ranges.

Monthly Maintenance:

- Remove any covers such as side shields and clean them and the areas they protect, clearing them of any debris.

- Clean all cooling components and check that they are working properly.

Quarterly Maintenance:

- Check the sprockets thoroughly for wear and replace any if necessary: warped sprockets can cause the chain to stretch.

- Check the chain thoroughly for wear and stretch.

- Check the alignment of the sprockets and axles.

- Check for any unusual wear, determine the cause and then fix it.

- If you have an automatic lubrication system set up for your chain, be sure to empty the reservoir and replace the oil filter.

It may not be quarterly, but at regular times throughout the year, look at your maintenance log and inspect the chain and conveyor lines. If there are any serious issues or concerning trends (such as incomplete or missing log entries), address the issue with your maintenance staff, as this may indicate that routine maintenance has been overlooked.

How to Choose the Right Chain Conveyor for Your Manufacturing Industry Requirements

To choose the right chain conveyor for your manufacturing needs, you need to consider the following factors:

- Load capacity: The load capacity will affect the size of the chain conveyor, the number of chains, and the conveyor structure.

- Size: Determine the size of the chain conveyor that is suitable for the manufacturing process and the size of the product to be conveyed.

- Product material: Consider the material of the product to be conveyed to choose the right type of chain conveyor. For example, if the product is easily damaged or scratched, you can choose a plastic-coated chain conveyor to reduce friction and avoid product damage.

- Working environment: Determine the working environment of the chain conveyor, such as temperature, humidity, chemical environment. You need to choose the right type of chain conveyor for the environment to ensure product durability and longevity.

- System Structure: Consider the structure of the system to choose the right type of chain conveyor for the system, including the distance between the chains, the speed of movement, and the direction of movement of the chain conveyor.

- Performance and reliability: Consider the performance and reliability of the chain conveyor to ensure that the product will operate well for a long time and will not cause problems or interruptions in the production process.

To choose the right chain conveyor for the requirements of the manufacturing industry, you need to consider many different factors and may need advice from chain conveyor experts to ensure the right and effective choice for your business.

How much does an industrial chain conveyor cost?

The price of an industrial chain conveyor can be considered expensive compared to some other products in the industry. However, this is a very necessary and important product in the production process of many industries, especially in the transportation of large and heavy goods.

The price of industrial chain conveyors depends on many factors such as size, material, product brand, and manufacturer. However, when investing in a chain conveyor system, users often focus on the quality and performance of the product. Therefore, when buying an industrial chain conveyor, price is not the only deciding factor, but other factors such as durability, longevity, accuracy, flexibility and compatibility with other equipment in the system must also be considered.

Reference price of industrial chain conveyors from 50,000,000 to billions of VND depending on the customer's installation requirements.

Address for installation of industrial chain conveyors on request

Intech Group has a lot of experience in manufacturing all kinds of industrial conveyors through research, development, production and installation for many different manufacturing industries. All conveyor systems are thoroughly tested and inspected to ensure you get a long-lasting, low-maintenance system. Chain conveyors are designed and installed by Intech according to customer requirements to ensure the best quality and price. This is our main conveyor product that has been invested in research to create the best product for customer needs.

Intech conveyors work perfectly to transport products of different sizes and weights. Customers who need to install chain conveyors and other types of industrial conveyors for their shipping needs can contact us for advice and support:

- Hotline: 024 66 806 795

- Address: Lot 6, Lai Xa Industrial Park, Tay Tuu Ward, Hanoi City