Conveyor belts are increasingly widely used in the manufacturing industry, bringing outstanding benefits. For each different industry, conveyor belts with different features will be selected to suit the environment and goods to be transported. Therefore, there are currently a variety of conveyor belts serving the most superior designs.

Commonly used types of conveyor belts today:

There are many types of conveyor belts used to assemble quality conveyor belts, meeting the purpose of use to achieve the most optimal efficiency. Each type of belt has different features, so you need to understand clearly to choose correctly. Below are the most commonly used types of conveyor belts today.

1 - Characteristics of PVC conveyor belts:

- PVC conveyor belts have good adhesion between layers, good friction resistance, high heat resistance and anti-sticking, little stretch, work well in harsh environments.

- PVC conveyor belts are mainly blue and white, in addition, the conveyor belts are also black and rough

- PVC belt thickness: from 0.8-5mm.

- PVC belts are available in smooth, rough or ribbed forms

- PVC conveyor belts are made of good materials, diverse designs, and flexible for customers to choose from.

* Application of PVC belts:

- Using PVC conveyor belts in making conveyor belts will help businesses save costs and increase production efficiency, so they are widely used in manufacturing industries, warehouses, shipping areas, airports, supermarkets

- PVC conveyor belts are most commonly used in food, beverage, pharmaceutical, electronic components production lines... to help move products flexibly, quickly and safely. Mini conveyor belts often use PVC belts to transport small and light materials.

- PVC conveyor belts are suitable for moving items of small and medium size and weight. Flexible in transporting goods of many different shapes.

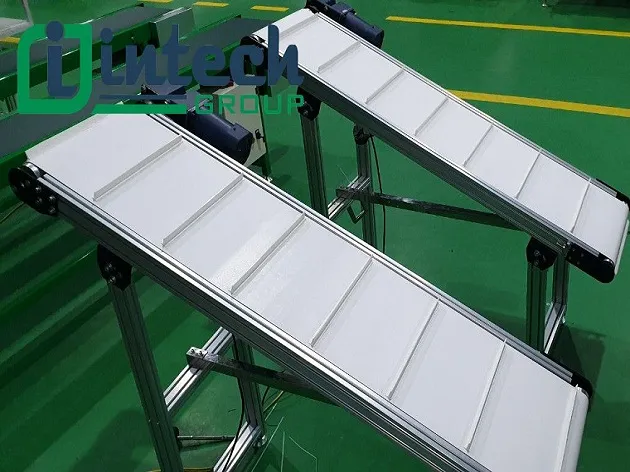

2 - Characteristics of ribbed conveyor belts:

- PVC, PU, rubber conveyor belts are ribbed horizontally, V ribbed, T ribbed depending on the purpose of use to increase friction and high load capacity, while preventing slipping during transportation.

- Ribbed belts are often used for inclined conveyors with ribs in the middle creating friction and traction at an inclination of 30-60 degrees, helping the material to be transported not to slide out.

* Application of ribbed conveyor belts:

- Ribbed conveyor belts are manufactured for applications of conveying goods to high places for small materials

- Using ribbed belts in conveyors makes it easier to classify goods during transportation.

- Ribbed conveyor belts are commonly used in industrial production lines, food industry, electronic components, pharmaceuticals, and are commonly used.

3 - Characteristics of PU conveyor belts:

- PU conveyor belts have a variety of thicknesses from 0.7-3mm

- Has good abrasion resistance, anti-static, oil resistance, water resistance, and good resistance to environmental impacts.

* Application of PU belts:

- Application as PU conveyor belts to transport goods in many manufacturing industries such as food, pharmaceuticals, electronics, etc.

- PU belts ensure hygiene, safety, and are non-toxic, so they are often used in the food, pharmaceutical, and medical industries.

- In addition, they are also used in conveyor belts for transporting goods in warehouses

4 - Characteristics of mesh conveyor belts:

- Mesh conveyor belts have a structure of stainless steel fibers interwoven into a mesh combined with iron in stainless steel on the outside with a conveyor chain attached.

- This is a type of conveyor belt with a high price, so it is often carefully considered before use

- Mesh conveyor belts are capable of withstanding high temperatures, retaining and transmitting heat well, and are not deformed by impact forces

- Easy to clean, ensuring high durability with the use of 304 stainless steel mesh

* Application of mesh belt conveyors:

- Stainless steel mesh conveyor belts are used to move hot, cold materials and harsh environments

- They are used in the food, confectionery, and seafood industries.

5 - Characteristics of chain conveyor belts

- Chain conveyor belts are often of 2 commonly used types: stainless steel chain conveyor belts and plastic chain conveyor belts.

- They are abrasion resistant, waterproof, easy to clean and maintain.

- Chain belts are durable and have good load capacity

* Application of chain belts:

- Chain belts in conveyors make it easy to transport heavy goods such as pallets

- Chain conveyors are used in light industry, beverage and food manufacturing and processing industries.

- Seafood processing industries commonly use stainless steel chain conveyors

- Plastic chain conveyors are suitable for food and beverage processing industries

6 - Characteristics of rubber conveyor belts

- Smooth rubber conveyor belts are diverse in design and features, often have low cost, high durability and good load capacity.

- Smooth rubber conveyor belts have widths from 300-2500mm, strength coefficients ranging from 100-500 N/mm, abrasion resistance 8-18 mpa.

- Ribbed rubber conveyor belts are usually thick with 3 types of ribs: horizontal ribs, V-ribbed ribs, T-ribbed ribs depending on the requirements and purposes of use to increase friction and prevent slipping.

- Heat-resistant rubber conveyor belts can withstand high temperatures up to 200 degrees Celsius.

* Applications of rubber belts:

- Smooth rubber conveyor belts are widely used in the manufacturing industry, an important and indispensable part in the structure of conveyor belts and conveyor belts. They are used to make trough conveyor belts, rubber conveyor belts to transport materials in cement factories, bricks, gravel, sand, etc.

- Ribbed rubber conveyor belts are often used for inclined conveyors with ribs in the middle creating friction and traction at an inclination of 30-60 degrees, helping the material to be transported not to slide out.

- In addition to the ability to withstand high temperatures for a long time, they also have extremely high friction and elasticity, high tension used in industrial production such as cast iron, steel, cement, etc.

A few notes when buying conveyor belts:

- The quality of the belt must ensure the fabric layer, rubber quality.

- The quality of the joints, from the conveyor belt cutting technique to the gluing technique such as the cut must be straight, when connecting the belt, the belt circumference must be even, not conical.

- There are many other factors, but these are the most important factors, directly affecting the life of the product.

Supplier of standard belt conveyors

Intech Group provides a variety of belt conveyors that ensure high quality standards. Our conveyors meet the needs of moving many types of materials quickly and easily in many manufacturing industries.

With a team of highly skilled workers in the industry, we are committed to providing the best quality of conveyor processing, as well as the best delivery time to our customers. Each type of conveyor belt has different properties, so customers need to understand clearly to use it effectively.

Contact to order:

- Address: Lot 6, Lai Xa Industrial Park, Tay Tuu Ward, Hanoi City

- Phone: 024 66 806 795

- Email: info@intech-group.vn

- Website: intechvietnam.com