Currently, in the industrial manufacturing industry, drying conveyors are popularly used in packaging production lines and transporting goods in the fields of agriculture, pharmaceuticals, food processing, electronics, etc.

Grasping this need, Intech Group has researched and launched more and more types of drying conveyors applying advanced and superior technologies, meeting the requirements of high temperature drying, stable and durable operation.

What is a drying conveyor?

Drying conveyor belt is a conveyor line that transports and dries raw materials in the food processing, chemical, assembly industries, etc. The raw materials to be dried will be spread evenly on the surface, then moved into the drying chamber.

The heating element has the effect of evenly heating all the dried materials. This conveyor line has a sturdy structure and the ability to work in harsh environments. Relay and alarm devices ensure safety when the drying cabinet first starts operating.

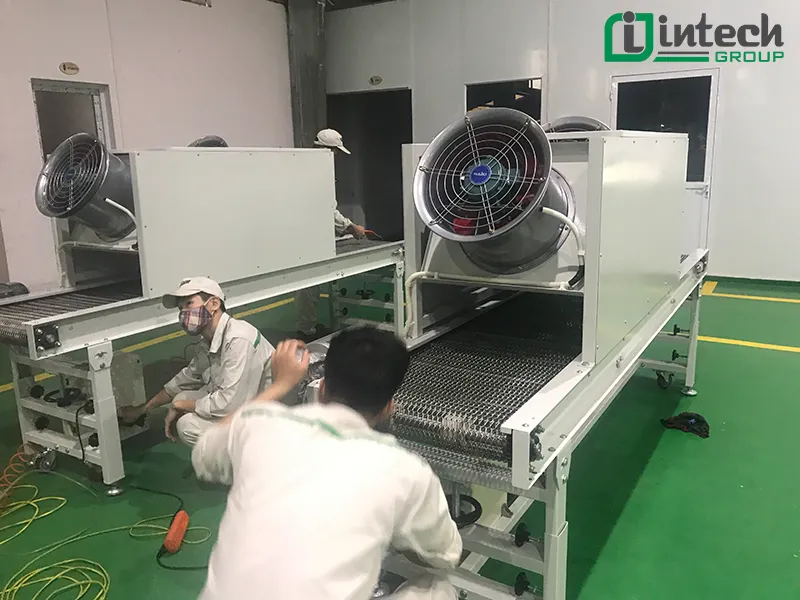

Image of Intech drying conveyor assembly

The purpose of using heat drying conveyor

Learn about the drying process is to reduce the mass of the material, heat is provided to the material by conduction, convection, radiation or high frequency electric field energy. The purpose of the drying process is to increase the durability of the material, better preservation. The initial drying material with high humidity is put into the drying conveyor, dried in the drying room and then taken out.

Structure of the drying conveyor

The structure of the drying conveyor includes the following parts:

- Conveyor frame: made of stainless steel, powder coated steel or aluminum profile.

+ Drying chamber width: 400 - 1500mm (depending on customer requirements).

+ Drying sail length: 1000- 5000mm (depending on customer requirements).

- Conveyor belt: made of heat-resistant PVC, PU, mesh chain, plate chain.

- Drying chamber:

+ Heating unit: Created by heating bars, UV lamps or Halogen lamps to maintain and stabilize the temperature in the drying chamber.

+ Drying temperature is divided into 2 levels: Low level 50°C -100°C, High temperature level from 100°C to 250°C

+ SSR control heat source for wide and stable temperature range 50-150°C, precise heat on/off.

+ The mechanism for lifting and lowering the drying heat exchanger helps to flexibly change the intensity of heat radiation to products of different sizes.

+ The drying chamber is insulated with glass wool.

- Motor and control cabinet

+ The motor uses a gear motor with a capacity of 0.1-2.2 Kw Voltage 220V - 1 phase or 3 phases.

+ Distribution cabinet / Stepless speed control can be equipped with additional frequency converter, sensor, timer, sensor, PLC, etc.

Basic structure of drying conveyor for food factory assembled by Intech

Classification of drying conveyor

Depending on the purpose and usage requirements, the manufacturer will advise and provide the appropriate type of drying conveyor. Currently, there are 2 basic types: Layer drying conveyor and food drying conveyor.

- Layer drying conveyor:

Including 1-layer, 2-layer and 3-layer drying conveyor depending on usage needs, designed with the ability to dry at the appropriate temperature for high efficiency. Layer drying conveyor is used to dry products while still maintaining the original quality of the finished product.

The drying conveyor is flexible in adjusting the temperature from low to high, the drying time is guaranteed to be fast and efficient. This conveyor mainly serves large-scale food and agricultural processing enterprises.

- Food drying conveyor:

Food drying conveyor is mainly used to dry fruits, food, fresh food, ... to reduce weight, help dry naturally and preserve for a long time while still maintaining the quality of the food.

Depending on the drying material, choose the conveyor with the appropriate size and drying chamber. This type of conveyor helps the drying process to be even, without missing anything, saving energy.

Operating principle of the drying conveyor

The material is spread evenly on the conveyor surface, then moves into the heating chamber for drying. The air is heated through the heat exchanger to ensure food hygiene and safety. The drying conveyor is integrated with a controller to help adjust the temperature to suit each stage and type of drying material.

When the material is on the conveyor surface, hot air will blow into the material from top to bottom, creating even heating for the entire material. The moisture content in the raw materials will gradually decrease, thereby drying the product while maintaining the content and nutrients in the food.

The drying conveyor is operated simply and flexibly thanks to the accompanying systems such as: relay, alarm to ensure safety. When the drying conveyor is started, the drying cabinet will run to avoid dangerous incidents

What should be noted when using a drying conveyor?

When using a drying conveyor, the following should be noted:

- Before operating, carefully check the locks, control panels, and wires

- Check and test the alarm system, power cord, and drying chamber

- Grasp the basic knowledge of conveyor operation: load capacity, temperature, rotating chamber, etc.

- Always keep a safe distance from the conveyor during operation

- Regularly clean and lubricate; maintain when necessary.

Criteria for choosing a drying conveyor?

When choosing a conveyor in general, a drying conveyor in particular; businesses need to consider the following criteria to make the most suitable choice:

- What type of drying conveyor does the business need?

There are many types of drying conveyors with different sizes, designs, and technical specifications. Depending on the usage requirements, choose the most suitable 1-layer, 2-layer or 3-layer type.

- Choose a quality drying conveyor

The conveyor surface needs to be even, the conveyor belt is taut and has good load-bearing capacity. The material used to make the conveyor is selected from durable materials, even heat dissipation, and easy to clean.

- Ability to integrate with the production system

If you buy a conveyor for the sole purpose of transporting individual goods, it will be easier to find a drying conveyor that is suitable for an existing production system. The drying conveyor must be able to integrate with the entire production process from installation to operation.

- Consider environmental conditions

Environmental factors to consider include: heat resistance, moisture resistance, chemical resistance, and abrasion resistance of the drying conveyor. Conveyors that can operate well in harsh environments will have better durability over time.

.webp)

How to effectively apply conveyor dryers

- In the food processing industry

- Drying meat, seafood, tea, etc.

- Baking products such as cakes, pizza.

- In the electronics and household goods industry

- Drying components after painting and gluing.

- Drying ink after printing logos and letters on products.

- In the spare parts manufacturing industry

- Drying products after painting or plating

- Drying assemblies and machines after complete assembly

- In the garment and footwear industry

- Drying finished clothing and footwear products

- Drying glue or chemicals after gluing.

Where to buy quality, good price heat drying conveyor belts?

To choose a quality conveyor belt supplier, please contact hotline 0983 113 387/ 0966 966 032, Intech Group will support customers 24/7 with other incentives such as:

- Get advice and support for designing 3D conveyor belts according to requirements completely free of charge. Get design plans from experts, provide drawings for businesses to choose the best products.

- Currently, Intech products are available and widely used in industrial factories across industrial parks in Vietnam.

- Our brand reputation and product quality bring many benefits to customers and are known by customers in the market, trusting to use our services.

Contact to buy Intech conveyor belts for the best price:

- Address: Lot 6, Lai Xa Industrial Park, Tay Tuu Ward, Hanoi City

- Phone: 0966 966 032

- Email: info@intech-group.vn

- Website: https://intechvietnam.com/