Mục lục

What is a vertical conveyor?

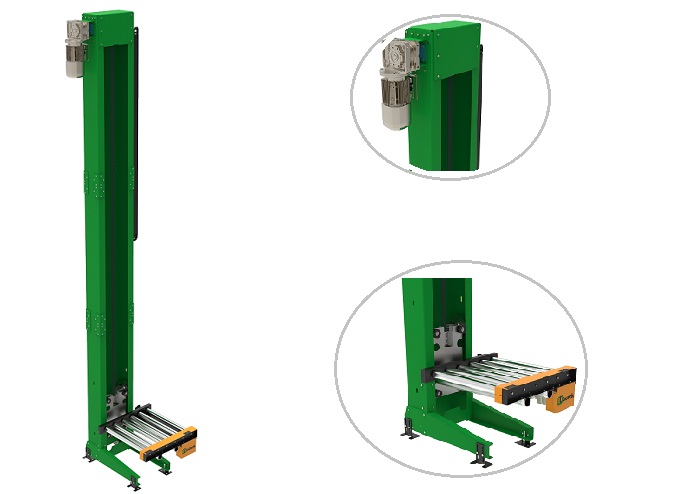

Vertical Conveyor Belt is used to transport goods vertically safely and efficiently over various distances. Vertical conveyors are often used for the purpose of moving goods up or down between floors or in a limited space.

Vertical conveyors are often used in applications that require vertical transportation, such as in manufacturing, assembly, packaging processes, or transporting from one floor to another in construction projects.

Vertical conveyors are designed and installed to suit the purpose of use, providing high efficiency. Helping to move goods simply and quickly with the ability to operate continuously and stably.

Commonly used types of vertical conveyors:

- Vertical chain conveyor: Uses chains to move products or materials vertically.

- Escalator conveyor: Is a type of conveyor with a ladder surface and operates like an escalator along a straight line.

- Screw Conveyor: Uses a rotating screw to push products or materials up or down.

Vertical conveyor applications are diverse, from industrial manufacturing to the freight transport sector.

| IT6110 | IT6210 | IT6310 |

|  |  |

Advantages of Vertical Conveyor Systems

Vertical conveyor systems offer unparalleled convenience and unmatched service, allowing users to automate production processes efficiently. Some of the advantages of a well-designed vertical conveyor include:

- Safe transport between multiple levels/elevations:

Vertical conveyor systems help transport goods safely between multiple levels and can bypass the hazards caused by conveyor operators. Moving fast, heavy loads, cartons, and packages is a job that vertical conveyors do in a flash. Additionally, these systems are clean, focused, and efficient, eliminating the possibility of injury when moving individual loads by hand. Vertical conveyors are simple to use, safe, and reduce risk compared to traditional methods.

- Space optimization:

Vertical conveyors are built to provide the customization you seek in conveyor systems for your organization. Our experts design and install them in a way that they utilize minimal space, provide high productivity, and operate smoothly.

- Energy Efficient:

Vertical conveyors are energy efficient and require little or no manpower to move materials from one level to another. They are faster than other means of moving materials at different levels, thus improving productivity.

- Labor Saving and Efficiency:

Vertical conveyors can cut costs by significantly reducing the amount of labor required to move materials to different levels. Since they can transport materials to different levels relatively much faster, they increase your efficiency.

- Economical:

Vertical conveyors are compact in design, using relatively little floor space. This leaves your floor space available for other uses in manufacturing or other conveyor systems. Apart from saving you money by reducing labour, improving efficiency and productivity, the costs associated with vertical conveyors are low and economical.

- Increased productivity:

As vertical conveyor systems carry materials and products wherever they are needed without human guidance, it can improve the efficiency of the entire workforce, eliminating the usual associated costs, human errors and unnecessary delays and thus vertical conveyors deliver greater throughput, higher capacity and productivity.

- Environmentally friendly and easy to clean:

All our conveyors are manufactured keeping in mind that they are designed and used in an environmentally friendly manner and can be cleaned easily. Since vertical conveyors ensure continuous movement of goods, the streams are cleaned regularly.

- Reduced costs:

Vertical conveyors tend to be a cost-effective solution for heavy lifting. Unlike forklifts, vertical reciprocating conveyors require minimal maintenance and inspection, which saves a lot of money.

- Modularity and Adaptability:

Vertical conveyors offer modularity and can adapt to the different requirements of different customers, work areas, weights handled, platform types, etc.

- Increased Profitability:

All the above advantages allow for higher productivity, space optimization, faster and smoother operations with good cost savings, ultimately leading to increased productivity and high profitability for the organization.

Some Applications of Vertical Conveyors

Vertical conveyors are used in a variety of applications in different industries. Here are some common applications of vertical conveyors:

- Vertical Conveyors in Industrial Manufacturing:

Vertical conveyors in industrial manufacturing play an important role in transporting products, materials or goods from one floor to another in the manufacturing process.

- Product Assembly: In the process of assembling complex products, vertical conveyors can be used to move components or products from one floor to another for assembly steps.

- Material Handling: In material handling processes such as screening, processing or recycling, vertical conveyors can be used to move materials from one floor to another for processing steps.

- In the packaging industry, vertical conveyors can be used to transport products to packaging lines, increasing efficiency and saving space.

- Vertical Conveyors in Construction

In construction projects, vertical conveyors can be used to transport building materials from one floor to another, optimizing movement and reducing labor.

- Transporting construction materials: Vertical conveyors can be used to transport building materials such as sand, stone, cement and bricks from one floor to the lower floor or vice versa. This saves time and effort of workers.

- Transporting heavy objects: In high-rise construction projects or large equipment, vertical conveyors can be used to transport equipment, machinery or heavy materials from one floor to another safely and efficiently.

- Transporting people and equipment: In some cases, vertical conveyors can be used to transport workers and equipment from the lower floor to the upper floor of a construction project.

- Transporting concrete or mortar: In the construction of high-rise buildings, vertical conveyors can be used to transport concrete or mortar from the ground to upper floors for concrete pouring work.

- Repair and maintenance: During the repair or maintenance of buildings or construction structures, vertical conveyors can assist in transporting materials and equipment to the required floors.

Using vertical conveyors in the construction industry can increase work efficiency, reduce labor, and optimize the construction process. However, the use of vertical conveyors must comply with safety regulations and be performed by people with relevant experience and training.

- Vertical conveyors in logistics and warehouses

In distribution centers and warehouses, vertical conveyors can be used to transport goods to upper floors to save storage space, helping to improve the efficiency of transporting and managing goods.

- Optimizing storage space: Vertical conveyors can help to utilize vertical space in the warehouse, thereby optimizing the arrangement and storage of goods. This increases storage capacity and reduces crowding.

- Moving goods along floors: Vertical conveyors allow goods to be transported from one floor to another in multi-level storage systems. This optimizes picking and ordering, reducing search and transport time.

- Handling and sorting of goods: Vertical conveyors can be used to transport goods from lower floors to higher floors for processing, quality inspection, packaging or sorting of goods.

- Packing and crating: In packing and crating centers, vertical conveyors can be used to transport goods from the production floor to the packing floor, optimizing the packing process and saving time.

Thus, vertical conveyors have many applications in many different fields, helping to optimize transportation and save space in industrial and manufacturing processes.

Intech Group installs reputable, quality vertical conveyors on demand

Intech Group has many years of experience providing reputable, quality conveyors at competitive prices. Intech conveyors not only specify length, width and other standard features but also provide complete customized solutions for material handling, manufacturing, assembly, packaging... Flexible and powerful as Intech's standard conveyor systems meet the strict requirements of many industries.

Customers need support to find a solution? Contact Intech online at www.intechvietnam.com or call Hotline: 0966 966 032. Our experienced sales staff are ready to support you.