Currently, in industrial production, conveyor belts play an important role in transporting goods and raw materials. In particular, plastic chain conveyors are one of the types of conveyor belts widely used in the food, pharmaceutical and beverage industries, bringing outstanding efficiency. Let's learn more about plastic chain conveyors with Intech.

What is a plastic chain conveyor?

A plastic chain conveyor is a transport device that uses plastic chains to move products from one location to another. The plastic chains are linked together to form a circulation, and when driven, it will pull the products placed on the moving surface. Plastic chains are made from plastics such as HDPE, PP, ... with high durability, good load capacity and many advantages compared to other types of conveyor belts.

Plastic chain conveyors are commonly used in many industries today

Characteristics and structure of plastic chain conveyors:

- Simple structure, sturdy, light weight, low noise.

- The ability to reduce noise emissions while ensuring long-term performance of the chain conveyor system is superior to metal chains.

- Using plastic chains has high durability, wear resistance and lower cost than metal.

- The conveyor is easy to disassemble when moving or regular maintenance.

- The plastic chain conveyor frame can use steel, stainless steel or aluminum profiles.

- The length and width of the conveyor are optional according to application requirements

- The chain material is POM plastic in brown, white

- Conveyor motor: uses inverter, gearbox, electrical cabinet, ...

- It is easily installed on a variety of terrains and shapes, including curves and straight lines, continuous operation.

Types of plastic chain conveyors commonly used in industry today

There are many types of plastic chain conveyors used in transporting goods today, below are the most popular types:

- Straight plastic chain conveyor

- Light, strong and beautiful.

- Does not slip when pulling luggage.

- Easy to disassemble and move.

- Simple mechanical structure, easy to disassemble and maintain.

- High efficiency and reliability in transmission.

- Helps improve productivity in the production process and facilitate quality control.

- Used to replace human power transportation and automate machine lines.

- Easy to replace and maintain.

Straight plastic chain conveyors are widely used in many industries

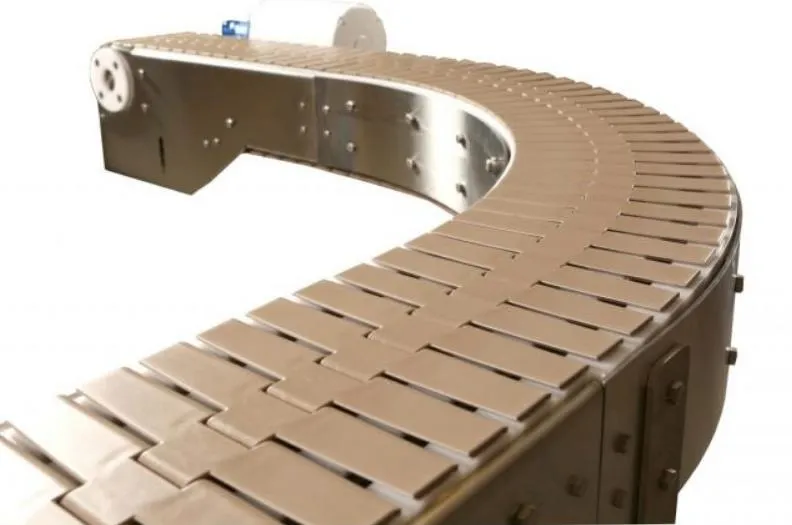

- Curved plastic chain conveyors

- Consists of plastic chains fixed vertically to form a transport surface of the desired length.

- The transport surface is supported by a stable steel frame.

- The links vary in width and shape depending on the model provided by the manufacturer.

- Lightweight and easy to install.

- Reduces the line traction and energy load, reducing costs for companies.

- Smooth operation with little noise

- Creates a 180-degree curved transport chain.

- The surface does not peel, wear, or mold due to long-term use.

Advantages of plastic chain conveyors:

There are many benefits associated with the use of chain conveyor systems in different industries. Some of them are:

- Easy installation:

The installation of this type of conveyor system is quite easy. That is why most manufacturers who create these systems come with installation services.

- Flexibility:

Another amazing thing about this system is its flexibility. Modifying or upgrading this system is easy and can be done with the help of the right tools.

This means that over time as your factory expands or your business increases, you will obviously need more conveyor systems to meet the growing demand, at which point you can easily upgrade your existing conveyor system. The good thing is that when you upgrade your system, you don’t need to buy a new one, just modify the one you have and the job will be done.

- Affordable:

The versatility, ease of use, and durability are what makes these systems affordable. In fact, with chain conveyors, you will never have to worry about any expensive repair or maintenance costs.

Disadvantages of plastic chain conveyors

- Plastic chain conveyors have low load capacity and low heat resistance

- Plastic can wear out and age over time, leading to a reduced conveyor life.

- In harsh environments, plastic chain conveyors can be damaged faster.

- Plastic chain conveyors have less impact resistance than other types of conveyors

Applications of plastic chain conveyors

There are many industries that rely on the operation of chain conveyor systems and therefore use this technology for their production lines. Plastic chain conveyors are adapting to handle more and more products, but it is most popular in food and pharmaceutical packaging applications.

The conveyor frame is made of 304 stainless steel and is suitable for the beverage industry, canned food, packaging, PET bottles and aluminum cans. Confectionery and beverage industries use plastic chain conveyors to increase production efficiency, save costs and transport time. Using plastic chains can reduce noise compared to metal chains but ensure long-term operation, high wear resistance and low maintenance costs of the chain system.

When to Use Plastic Chain Conveyors?

When to Consider Plastic Chain Conveyors:

1 - Small Products

Plastic chain conveyors can handle a wide range of product sizes, however a huge advantage is that they can handle extremely small products. If your company specializes in manufacturing or distributing small goods such as bottled beverages, small goods, canned foods, medical products, pharmaceuticals and cosmetics, then you should consider a plastic chain conveyor system.

Plastic chains used as conveying surfaces are highly customizable and can be manufactured in small widths to convey any given product specification.

2 - Limited Space

Plastic chain conveyors are much smaller in size than other conveying products. They are capable of making small tight turns and can have some curved and straight sections provided by a drive due to the low coefficient of friction of the plastic chain. This will reduce operating costs compared to other conveyor models.

Another significant advantage to plastic chain conveyors when it comes to space utilization is that the system can be designed and customized to incorporate other ancillary equipment. This can create a smooth working system, reducing wasted time during conveying.

3 - Special Applications

When complex applications are required, plastic chain conveyors are very versatile. Plastic chain conveyors are easily adapted to incorporate each customer’s needs. Plastic chain conveyors can move items easily with the ability to be washed down and can use some plastic belts that can go through a UV oven for treatment if required.

Due to the customization aspect of plastic chain conveyors, the price for them can be higher than other conveyor options, but all the benefits that plastic chain conveyors bring certainly outweigh the cost of the investment.

Contact to order plastic chain conveyor at the best price

Intech Group specializes in manufacturing industrial chain conveyors according to international standards at competitive prices. Conveyors are commonly used in manufacturing industries to increase efficiency, reduce labor costs and save production time.

Our industrial conveyors are designed based on customers' production requirements. We are willing to survey customers' production sites to advise customers on choosing the right automatic conveyor.

Intech is confident to make you satisfied with both quality and price. Please give us your trust and we will respond to you with the best quality products!

Contact to order conveyors at Hotline: 0966 966 032