Mục lục

Rubber conveyor belts are one of the most popular types of conveyor belts and are widely used in many industries, especially heavy industries. There are many types of rubber conveyor belts used with many different advantages. Below, we will learn in detail about the industrial rubber conveyor belts commonly used today.

What is a rubber conveyor belt?

A rubber conveyor belt is a type of conveyor belt with a large load-bearing capacity, made of a thick layer of high-strength rubber with a structure made of polyamide, synthetic polyester and super-durable polyamide fibers. These materials are waterproof as well as very resistant to wet weather conditions or mold. But besides that, rubber conveyor belts are also known for their ability to transport large volumes of raw materials and goods at high speeds even over long distances.

The structure of the rubber conveyor belt includes the following main parts:

- Conveyor belt: Fabric rubber, Ninon rubber, thickness from 2mm to 12mm.

- Conveyor frame: Usually made of steel, stainless steel, or aluminum profile.

- Traction roller: Usually made of galvanized steel, stainless steel, diameter 89mm, 102mm, 133mm.

- Traction motor: Is a speed reducer motor, capacity from 0.4KW to 3.2KW.

- Transmission mechanism: Driven by chain sprocket or belt.

- Rollers made of steel, stainless steel, or rubber

- Control cabinet: Includes inverter, sensor, PLC,... and electrical switching devices.

- In addition, there are other auxiliary devices depending on the application of the conveyor.

Outstanding advantages of rubber conveyor belts:

- Rubber conveyor belts have high friction, there are ribbed rubber conveyor belts to load materials up high without fear of the material sliding back.

- Using V-ribbed rubber conveyor belts for sliding raw materials with the purpose of creating a fixed angle of inclination will create resistance for the raw materials to move stably.

- Flexibility, stiffness, reliability, elasticity, resilience and stability are the main properties of rubber conveyor belts that allow the efficient conveyance of products and thus excel in the requirements of light, medium and even heavier loads.

- Rubber conveyor belts are very durable, can withstand heavy loads, withstand environmental impacts, high temperatures, strong impacts, etc.

- High-temperature resistant rubber conveyor belts are suitable for harsh working environments such as the mining industry

- Rubber conveyor belts are easy to install and maintain

How to maintain and service rubber conveyor belts?

To maintain and service rubber conveyor belts, you can follow these instructions:

- Periodic inspection: You should periodically inspect the conveyor belt to ensure it is operating at its best. The appropriate inspection time depends on the frequency of use and the working conditions of the conveyor belt.

- Periodic cleaning: You should periodically clean the conveyor belt to remove dirt, debris or any other substances on the conveyor belt surface. This will help reduce friction and prolong the life of the conveyor belt.

- Lubrication: You should periodically lubricate the conveyor belt to ensure reduced friction and increased life of the conveyor belt. However, it is important to use the right type of lubricant for the rubber conveyor belt to avoid damaging the conveyor surface.

- Check the tension of the conveyor belt: You should check the tension of the conveyor belt to ensure it is operating at the correct level and to ensure the durability of the conveyor belt.

- Check the accuracy: You should check the accuracy of the conveyor belt to ensure it is operating accurately and meeting your work requirements.

- Replace the conveyor belt when necessary: You should replace the conveyor belt when necessary to ensure the conveyor belt is operating at its best level and to ensure the safety of your work.

Maintenance and upkeep of cheap rubber conveyor belts requires attention and attention to detail. You should follow the above instructions to ensure the conveyor belt is operating at its best level and has high durability.

Applications of industrial rubber conveyor belts:

Rubber conveyor belts transport many types of materials quickly and efficiently to other production stages to ensure stable and continuous operation during the production process.

- Food production is considered a field where rubber conveyor belts are widely applied because common materials undergo processing in many stages with different equipment. Rubber conveyor belts have been and are showing their superior application features in this field.

- Used in transporting goods, packaging, connecting transmission systems, and factory lines.

- Used in mining industries such as coal, sand, gravel, ore, cement, etc.

- Metallurgical industry: Cheap rubber conveyor belts are used to transport and convert products and raw materials in the production and metallurgical process.

- Building materials industry: Cheap rubber conveyor belts are used to transport products and raw materials in the production of building materials.

Top 6 Most Popular Industrial Rubber Conveyor Belts Today

Rubber conveyor belts are used effectively in heavy-duty applications in industrial and mining manufacturing industries. This type of conveyor belt is highly appreciated for its performance and durability. Currently, there are many types of rubber conveyor belts with different features and applications suitable for each job requirement to bring optimal transmission efficiency.

1 - Mini rubber conveyor belt: Optimal energy saving

Mini rubber conveyor belts are small versions of large rubber conveyor belts, so they have the same features. However, mini rubber conveyor belts are more suitable for small and short-distance transportation tasks

* Outstanding features of mini rubber conveyor belts:

- Sturdy steel conveyor frame, good load-bearing capacity

- Blue-black flat rubber belt, 1mm thick

- Maximum width 500mm

- Anti-static ability

- Can work in many degrees 20-80 degrees C

- 220V/50Hz AC power supply

- Small rubber conveyor belt design, convenient to use

* Application of mini rubber conveyor belts:

- Mini rubber conveyor belts are compact in size, energy-saving, and wear-resistant, so they are used in many fields. They can be found in manufacturing and processing industries, etc.

- Rubber conveyor belts with inclined design are used in the process of transporting goods onto trucks, containers or in warehouse areas or small factories. Using rubber conveyor belts is very flexible and convenient, making the process of transporting goods easy, saving human labor.

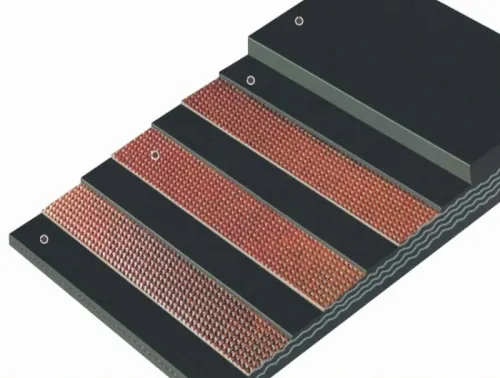

2 - Fabric rubber conveyor belt: High durability, warranty up to 24 months

Fabric rubber conveyor belts have many outstanding features for optimal operation. This is a type of conveyor belt with woven fiber belts that help the conveyor belt have high durability, while limiting deformation during operation.

* Characteristics of fabric rubber conveyor belts

- Fabric rubber conveyor belts with cotton or pure nylon belts have good adhesion to rubber.

- Cotton fabric conveyor belt has outstanding advantages of good flexibility, good trough capacity, low price

- Nylon fabric conveyor belt is wear-resistant, fatigue-resistant, high working intensity, good heat resistance

- Polyester fabric rubber conveyor belt has low elongation, good heat resistance, low price. They have good impact resistance.

* Fabric rubber conveyor belt application

- Fabric rubber conveyor belt is mainly suitable for transporting lumpy and small powder materials (wood chips, rice, cement and ore over medium, short or long distances.

- Fabric rubber conveyor belt has good troughing ability, so it is often used in the mining industry, transporting large loads.

3 - V-ribbed rubber conveyor belt: Safe and efficient loading of goods

V-ribbed rubber conveyor belt has an inclined design with V-shaped ribs to increase friction for the conveyor belt, helping to transport goods to high places safely and efficiently.

* Outstanding features of V-ribbed rubber conveyor belt

- V-ribbed rubber belt has high abrasion resistance and good impact resistance. V-ribbed ribs on the conveyor belt help increase friction during movement

- Large conveyor capacity, smooth operation of many types of large materials, large size channel

- Black ribbed conveyor belt with standard widths B500, B600, B650, B800, B1000, B1200

- Conveyor frame made of powder coated steel, sturdy, good load-bearing

- Controller includes inverter, emergency stop button, power supply

- Standard conveyor motor, high quality

- V rib height from 5 to 30mm

* V ribbed rubber conveyor belt application

- V ribbed rubber conveyor belts provide conveyor tracking support and help prevent track slippage. They are ideal for applications where the conveyor is long and narrow or wide and short, especially where the conveyor tends to distribute the load unevenly along its surface area.

- Because V-shaped guides improve tracking consistency, they extend the life of the conveyor by reducing the amount of wear on both edges. In addition, improved tracking reduces conveyor failures, improving uptime conveyor belt and your production output.

- V-ribbed rubber conveyor belts are often used in agriculture and industry to help transport goods to high places and onto containers safely and effectively.

4 - Rubber conveyor belt with ruffled ears: Safe and efficient transportation of small materials

Rubber conveyor belt with ruffled ears is an effective means of transporting goods in many industrial and mining industries. The conveyor belt has ruffled ears on both sides along the belt, helping to move goods up high safely and efficiently

* Outstanding features of rubber conveyor belt with ruffled ears:

- Rubber conveyor belt with ruffled ears is sturdy, durable, and has a very good load capacity

- The ruffled ears are molded on both sides of the conveyor belt to help protect the product when moving. The rubber conveyor belt also has compartments inside the conveyor belt to create space for materials to move up easily without falling and sliding down

- The conveyor belt is designed with different thicknesses, usually from 3 to 6 layers

- The steel conveyor frame is sturdy, can be fixed or moved

- The motor and control cabinet are designed according to standards, ensuring the conveyor belt operates smoothly

- The rubber conveyor belt operates stably, durably, smoothly, saving labor costs for transportation

* Application of rubber conveyor belt

- Rubber conveyor belt is used in many industries, agriculture, mining, bringing high efficiency in the transportation process

- The conveyor belt can transport fragile products, loose particles or powder

- Effective application in transporting goods uphill with high slopes.

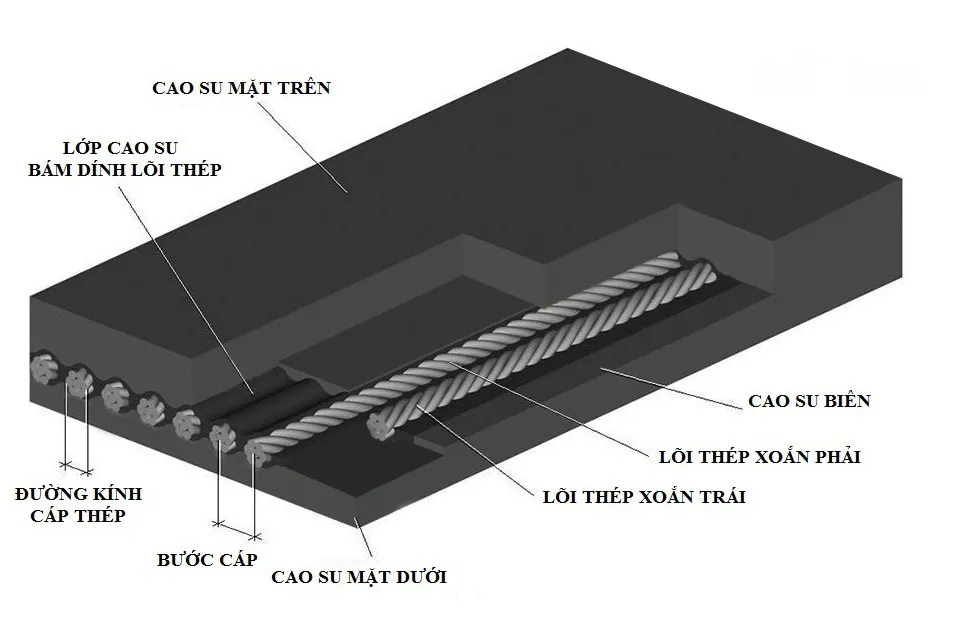

5 - Steel core rubber conveyor belt: Best for heavy loads

The steel core rubber conveyor belt is a special type of conveyor belt used in production lines with high harshness. The conveyor belt is specially designed to load heavy loads quickly and easily.

* Outstanding features of the steel core rubber conveyor belt:

- The steel cable structure of the conveyor belt has good load-bearing capacity, making it easy to load heavy loads. Steel cables are arranged parallel to each other along the conveyor belt surface to create balance and stability during operation

- The steel wires are covered with a layer of rubber on the surface to increase the life and durability of the conveyor belt

- The rubber surface is impact-resistant and abrasion-resistant

- Steel cables and rubber are processed with high technology to ensure good bonding and durability when used

- The rubber of the steel wire rubber conveyor belt adheres firmly to the steel cable and is impact-resistant, increasing the life of the conveyor belt. The steel cable is uniformly structured and has the same tension to help the belt stay upright and operate effectively.

- Steel cables have good load-bearing capacity, very low elongation, increasing the durability of the conveyor belt

* Application of steel core rubber conveyor belts

- Steel core rubber conveyor belts are used in long production lines, can carry large and heavy loads. Used in outdoor constructions, in difficult terrains and harsh working environments

- Steel cable rubber conveyor belts are often used to transport products with long distances, heavy loads, and high resistance. Steel cable conveyor belts are also used in high-speed transportation over short distances.

- With fast processing speed, steel core rubber conveyor belts are effectively used in heavy industries, thermal power plants, iron and steel, mining...

6 - Trough rubber conveyor belt: A powerful tool for transporting small-sized goods

Trough rubber conveyor belts are designed to hold loose materials in the middle of the conveyor belt. Trough rubber belts are suitable for transporting large quantities of loose materials over long distances easily without spilling out of the conveyor belt

* Outstanding features of trough rubber conveyor belts

- Trough rubber conveyor belts are designed with smart troughs to easily transport loose, small, powdery goods easily without falling out

- The conveyor frame is sturdy, has good load-bearing capacity, is made of steel, stainless steel or electrostatically painted iron

- The rubber conveyor belt is smooth or can be ribbed

- The conveyor belt has a standard control system for durable, smooth operation

- Conveyor belt maintenance is easy with reasonable investment costs

* Trough rubber conveyor belt applications

- Trough rubber conveyor belts are mainly used to transport small materials in large quantities such as sand, gravel, coal, powder, etc.

- Conveyors are found in many mining and construction factories or in some industrial and agricultural production fields

- Suitable for transporting goods in complex terrains, can be designed horizontal or inclined design.

Notes on buying cheap rubber conveyor belts

If you are looking for cheap rubber conveyor belts, here are some notes for you to consider:

- Product quality:

You should choose rubber conveyor belts made from high-quality rubber materials to ensure the longevity and performance of the product. Avoid products made from recycled rubber or poor quality materials.

- Check the size:

When buying rubber conveyor belts, you need to measure the size of the product that needs to be replaced to choose a product that fits that size. If the conveyor belt is too short or too long, it will not work effectively and may lead to damage.

- Product brand:

You should choose products from reputable and good quality brands to ensure that the product is manufactured and fully quality tested.

- Price:

Do not choose a product that is too cheap because cheap products often use poor quality or old materials, which can reduce the life and performance of the product.

- Support service:

You should choose a supplier with good support service and provide complete product information to help you choose the most suitable product.

In short, when buying cheap rubber conveyor belts, you need to consider product quality, product size, brand, price and support service of the supplier to ensure that you buy the right product and good quality.

How to choose the right rubber conveyor belt for high efficiency?

Choosing the right rubber conveyor belt for the job requires you to determine the basic technical requirements, working conditions and purpose of the conveyor belt. Here are some factors you may need to consider when choosing a rubber conveyor belt:

- Load capacity: You need to determine the volume and size of the material to be conveyed to choose a conveyor belt with the appropriate load capacity.

- Length and width: You need to determine the length and width of the conveyor belt to ensure it is suitable for the size of the work area.

- Travel speed: You need to determine the travel speed of the conveyor belt to choose a conveyor belt with the appropriate load capacity and durability.

- Thickness and stiffness of the conveyor belt: You need to determine the thickness and stiffness of the conveyor belt to ensure it is strong enough to withstand the load and has good durability.

- Working conditions: You need to determine the working conditions such as temperature, humidity, chemicals... to choose a conveyor belt that is capable of withstanding those working conditions.

- Purpose of use: You need to determine the purpose of the conveyor belt to choose the type of conveyor belt suitable for the job requirements such as transporting heavy materials, transporting in wet environments, transporting in chemical environments...

Choosing the right rubber conveyor belt for the job requires you to analyze and evaluate some basic technical factors, working conditions and the purpose of the conveyor belt to ensure that you choose the right conveyor belt for the job requirements.

How much is the current price of a rubber conveyor belt?

The average price of a rubber conveyor belt ranges from 200,000,000 VND to billions of VND. The important factor in pricing a rubber conveyor belt is its overall size. Size is measured in a number of different ways such as length, width, size of the drive pulley,... The larger the rubber conveyor system installed, the higher the cost.

Intech Group installs the best price industrial rubber conveyor belts

Rubber conveyor belts will excel in all conditions, however, choosing the right type is equally essential for the efficiency and operating life of the conveyor. If you are not confident in choosing the type of conveyor for your application requirements, Intech conveyor company is ready to help you do that.

Intech provides free advice to customers on the type of conveyor belt suitable for their needs, the technical team will discuss with you, analyze your application area and accordingly suggest you the right type of rubber conveyor belt to last longer and bring the highest results.

Intech rubber conveyor belt benefits for your business:

- Rubber conveyor belts are made from quality tested rubber materials and are therefore capable of conveying any type of rubber material efficiently.

- From small to large sized materials, our high tensile strength and stiffness allow our rubber conveyor belts to excel for any type of product.

- Since rubber is highly versatile, we can design and develop rubber conveyor belts according to user requirements to give you a higher return on investment.

- Whether it is horizontal, inclined or a combination of both, our rubber conveyor belts can carry materials easily with minimal material loss.

- The high impact resistance of rubber makes it hot for heavy materials such as wood, ore, coal, etc.

- The rubber material reduces vibration, noise, while the remarkable stiffness of our rubber conveyor belts reduces power consumption.

- Intech's rubber conveyor belts comply with ISO quality standards and food safety standards and are therefore ideal for conveying any type of product without difficulty.

Request a quote for a custom rubber conveyor system

At Intech Group, we have many years of experience in installing conveyors based on the specific requirements of our customers. Contact Intech for conveyor estimates and custom conveyor solutions for the most difficult production configurations. Intech is here to help you make it easier to choose quality products and save costs in the long run.

Contact Intech rubber conveyors today for the best price quote:

- Phone: 024 66 806 795

- Email: info@intech-group.vn