-

90 degree curved plastic chain conveyor

The 90 degree curved plastic chain conveyor is not only a conveying device but also an important component, contributing to the overall flexibility and efficiency of modern production lines.

-

Plastic parts conveyor belt

Intech Group specializes in manufacturing conveyor belts for transporting automotive plastic components, specially designed for each molding station, helping to automate and improve production efficiency.

-

Reversible 2-level Belt Conveyor

2-layer PVC conveyor belt is designed to transport many products in a short time, helping to save production time.

-

Chain conveyor for moving pallets containing car tires

Chain conveyor system optimized for transporting tire pallets with a maximum weight of 1000 kg, ensuring high performance and outstanding durability

-

PU Conveyor Belt

PU conveyor belt, quality PU conveyor system installed with Japanese technology is applied in food factories, confectionery, fruit processing, agricultural and aquatic products, bringing high economic efficiency and meeting food safety requirements.

-

Ribbed Conveyor

Ribbed conveyor belts are used to separate products as they move on the conveyor.

-

Conveyor lifts to transfer goods to the truck

Intech assembles conveyor belts to lift and lower goods onto cars or containers or to transfer goods in warehouses and factories, which are very popularly used by businesses today.

-

Conveyor with 2 side working table

A dual-side workbench conveyor is a type of industrial conveyor that is integrated with two additional workbenches (workbenches) on both sides of the conveyor belt.

-

PVC Conveyor

PVC conveyor belts are widely used in industrial production lines to help speed up the production process, create high efficiency, and ensure continuous production.

-

Plastic Chain Conveyor

Production of high-durability plastic chain conveyors, good abrasion resistance, low installation costs, so many businesses choose them for their production sector.

-

Stainless steel chain conveyor

Conveyor belts use high-strength, rust-resistant stainless steel material, so they are often used in harsh environments.

-

Folding Conveyor

Simple folding PVC conveyor belt structure, Intech designed the inclination depending on customer requirements to ensure the best performance of the conveyor belt.

-

Conveyor Mini

Intech manufactures and installs Mini Conveyors, small conveyors, and electronic component conveyors with the largest and most prestigious reputation in the country, supplying nationwide.

-

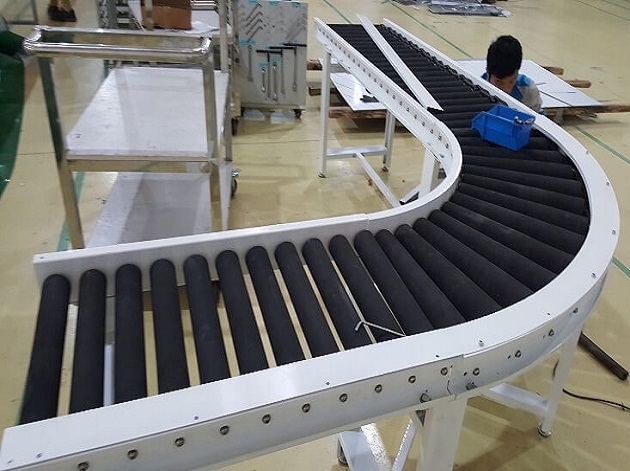

Curve Conveyors

Intech designs curved conveyors with conveyor angles designed to suit the intended use: 30, 45, 60, 90, 180 degrees.

-

Drying Conveyor

The drying conveyor belt is simple to operate, highly safe, has a safe conveyor dryer system such as relay, alarm, heat-resistant drying conveyor belt, durable, not deformed, widely used in production.

-

Chain Conveyors

Chain conveyors are used to move materials in production lines, chain conveyor systems are easy to install, require minimal maintenance and are cost effective.

-

Bucket Conveyor

Specialized bucket conveyor used to transport goods to high places to avoid falling and damaging the product, bucket conveyor is suitable for transporting small products.

-

Retractable conveyor

Retractable conveyor is a smart, flexible and efficient transportation solution, meeting the diverse needs of industries and life.

INTECH CONVEYOR - INDUSTRIAL CONVENIENT SYSTEM

Intech Conveyors - Conveyor systems for industrial production automation. Intech Group is proud to be a reputable manufacturer, helping businesses and factories nationwide to automate production systems. Designed and assembled by us to ensure quality according to International standards.

Intech Group has invested in researching new manufacturing technologies, learning and applying modern scientific achievements, investing in advanced specialized equipment and machinery to maximize production efficiency. We regularly participate in science and technology fairs as well as continuously send engineers to participate in seminars and advanced technical classes to meet the rigorous requirements of production.

Intech manufactures conveyor belts with many outstanding advantages:

- Intech conveyor belts ensure high quality and effective use because they are thoroughly researched and developed before being manufactured and delivered to customers.

- Standard modular design should be able to quickly disassemble and change easily.

- There are options for customers to choose from to ensure maximum efficiency.

- Increase transmission speed, reduce transportation time, increase labor productivity.

- Reduce labor costs for moving materials.

- Easy to operate, replace and maintain.

- Always give dedicated advice and put the interests of customers first.

How is Intech Conveyor designed?

Intech conveyor belts are designed to simulate on 3D software and have a "R&D" product research and development department, so the products are processed, manufactured, tested and evaluated for quality, durability, and aesthetics very carefully. before production and sold to customers. That is the difference between Intech Group and other companies in Vietnam.

- Frame system: Usually made of aluminum profile, powder coated steel or stainless steel.

- Conveyor belt: Usually 2mm and 3mm thick PVC tape or 1.5mm thick PU tape or using conveyor rollers depending on customer requirements.

- Traction roller in galvanized steel or aluminum Ø50, Ø60, Ø76, Ø89, Ø102 ...

- Roller supporting galvanized steel or stainless steel Ø25, Ø32, Ø38.

- Controller : Inverter, sensor, timer, sensor, PLC,...

- Chain or belt drive conveyors.

- Geared motor with capacity from 25W to 2.2KW.

There are also a number of other components depending on the application of the conveyor system (Conveyor System). All parts are designed rationally, scientifically, optimally to bring high efficiency.

Conveyor used in which field?

Conveyor systems are widely used in many industries due to the many benefits they offer:

- Conveyors can safely transport materials from one level to another, which, when done by human labor, would be difficult and costly.

- They can be installed almost anywhere and are much safer than using forklifts or other machinery to move materials.

- They can move a wide range of shapes, sizes and weights. In addition, many devices include advanced safety features that help prevent accidents.

- There are many options available to operate the conveying system, including hydraulic , mechanical and fully automatic systems, equipped to suit individual needs.

Conveyor systems are commonly used in many industries, including Mining, Automotive, Agriculture, Computers, Electronics, Food Processing, Aerospace, Pharmaceuticals, Chemicals, and Packaging. bottles and canning, printing finishing and packing,.... Although a wide variety of materials can be transported, some of the most common include food items such as: beans and nuts, bottles and cans , auto parts, scrap metal, medicine and powder, wood and furniture, grain and fodder,...

There are many important factors in choosing the correct conveyor system. It is important for you to know how a conveyor system will help in your field. Several areas are required to adopt a conveyor system such as: conveying, agglomeration and grading, material size, weight and shape and where loading and receiving points are required.

How much does a conveyor system cost?

The cost of the cheap or expensive system is not the story of the initial investment cost, but depends on the "value brought". No matter how cheap the system is, if it does not meet the needs of the user properly and fully, it is definitely an expensive product. And a product that, although expensive at first, has "value brought" in the end, it is a cheap product. So take a close look at the market and make your decision accordingly.

When you invest in a conveyor system, you need to keep in mind that the conveyor will also reduce your overall system operating costs. The cost depends on the type of conveyor belt, length, speed, size and method of conveying.

How to maintain conveyor system?

Conveyor systems are an effective solution in moving the company's products. Steps a company can take to ensure that it is operating at peak capacity include:

- Regular check-ups and system reviews

- Closely monitor the motor and reducer

- Train staff to operate according to manufacturer's standards.

Choosing the right type of conveyor, designing the right system and paying attention to regular maintenance practices, etc. will also help increase the life of your conveyor system.

A properly designed conveyor system will last a long time if properly maintained. Overhead conveyor systems have been used in many applications from store displays, assembly lines to paint finishing plants and more.

Intech Conveyors - Our Solution, Your Success!

Conveyor systems manufactured by Intech Group always require materials suitable for heavy load displacement and wear resistance to hold over time without shrinking due to deformation.

If you need a conveyor system, whether it is logistics, food industry or commercial use, Intech Group can help and discuss with you what you need and design a custom solution. for your business. If you are unsure about conveyor systems and how they can benefit your business by increasing throughput and reducing costs, contact Intech Group for assistance.

Intech Group has more than 10 years of presence in the Vietnam market, making its mark in many big projects in Vietnam and exporting to the international market. Satisfy the maximum benefits of customers "Quality products - Professional services - Competitive prices".

CONTACT:

- Hotline: 0966966032

- Email: Info@intech-group.vn

- Address: Lot 6, Lai Xa Industrial Cluster, Tay Tuu Ward, Hanoi City

Những câu hỏi thường gặp