Understand the beverage production line

12-08-2025 320

Beverage production lines play an important role in automating the process, from raw material processing to finished product packaging, helping businesses optimize costs and meet food safety standards.

Mục lục

So what are the stages, machines and how does a beverage production line work? Let's find out the details through the article below!

What is a beverage production line?

A beverage production line is a system of automatic or semi-automatic equipment and machines used to produce, process, package and finish beverages such as soft drinks, fruit juices, bottled tea, purified water, nut milk, etc.

This process includes many important stages such as water treatment, raw material mixing, bottling, sterilization, labeling and packaging products.

Each stage in the line is designed to ensure quality, food hygiene and safety and high productivity. Depending on the scale and type of product, factories can use modern technologies such as hot filling, aseptic cold filling or UHT sterilization to optimize the production process.

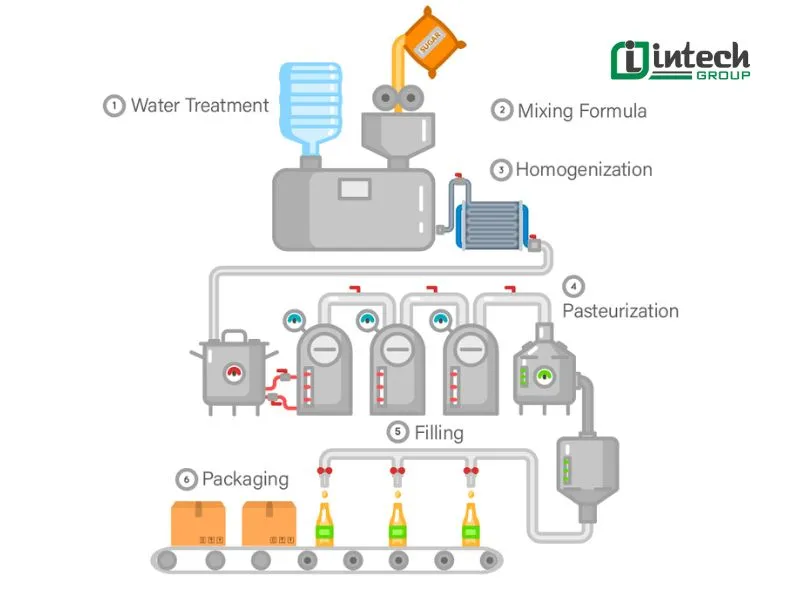

Process in the beverage production line

The beverage production process is very complex and varies between manufacturers. Each enterprise has its own production process and methods to optimize product quality and protect its trade secrets. However, there are some important stages that all beverage factories must perform.

- Water treatment

Water plays an important role in beverage production. It is not only used for mixing but also for cleaning the factory, sterilizing and performing many other steps. Therefore, most factories will use available water sources, which can be tap water or water from underground aquifers (requiring large investments).

Regardless of the source of water, the factory still needs to treat it before use in order to:

- Ensure water is safe for human health.

- Maintain a stable flavor of the product (because even pure water has its own flavor).

The water treatment process in a beverage factory usually includes the following steps:

- Cleaning and filtering water: Remove dirt, algae and impurities.

- Disinfection: Use chemicals (such as chlorine, fluoride) or activated carbon filters to kill bacteria and pathogens.

- RO filtration (reverse osmosis): Remove remaining impurities and chemicals.

After treatment, the water will be used to mix soft drinks, clean equipment and many other purposes in the factory.

- Prepare commercial production formula

To produce any type of beverage, the factory needs to develop a commercial product formula. This formula will specify the exact proportions of ingredients such as water, flavorings, food coloring, minerals, fresh ingredients and other additives.

This step ensures that every production batch has consistent quality and taste. In addition, commercial formulations must also control factors such as: flavor, color, texture, nutritional value, sweetness, shelf life and drinking experience.

- Homogenization

Achieving uniformity in beverage production is a major challenge. Liquids are unstable and are prone to sedimentation or clumping.

Clumping can occur when powders are not completely dissolved or when solid ingredients (such as fruit) are not ground sufficiently. This can clog filling and pumping nozzles, causing production interruptions and increased repair costs.

To prevent this, the plant will apply a variety of quality control measures:

- Using centrifuges and blenders to create smooth, homogeneous liquids.

- The mixing tank system will heat and completely dissolve granular ingredients (sugar, vitamins, etc.).

- Filters in the pipeline will remove large particles.

In addition, many factories also install homogenizers to grind and mix all ingredients evenly, helping the product achieve the highest quality.

- Filling liquid into packaging

Filling is the most important step in the beverage production process. This is the stage where the product is packaged into its packaging. Filling machines will automatically fill the packaging, inject liquid, and then seal it tightly to ensure product quality.

Common types of packaging in the beverage industry include: aluminum cans, plastic bottles, glass bottles, sterile paper cartons, and sterile bags. Each type of packaging will require a different type of filling machine.

In addition, the technology used in the filling process is also very important because it affects the quality, flavor, and food safety of the product. Below are the three most common filling methods:

- Hot Filling: The beverage is sterilized at high temperatures and pumped directly into the packaging. The heat from the liquid also helps kill bacteria inside the packaging. The filling temperature will depend on the packaging material (aluminum cans, plastic bottles, etc.) and the heat resistance of the product.

- Cold Filling or Aseptic Filling: The liquid is sterilized by various methods (heat, pressure, etc.), then cooled to about 5°C to preserve the flavor. The product is then filled into aseptic packaging (bags, boxes, etc.) in a sterile environment.

- Retort Processing: Applied to canned beverages, combining hot filling and retort sterilization. The product is sterilized twice: once when the hot liquid is pumped into the can, and the second time when the can is steamed in a retort machine to completely sterilize.

Each type of product, packaging, and filling machine will require a separate processing method and filling technology.

- Pasteurization

Sterilization is an important step to ensure food safety in beverage production. This technology helps the product have a longer shelf life and is safer for consumers, while increasing the commercial value of the product.

Most sterilization methods in beverage production use heat and steam to kill bacteria. Here are some common sterilization methods:

- UHT (Ultra-High Temperature) sterilization: The product is heated to 140°C for 5-6 seconds using a heat-retaining tube system before cooling and packaging.

- HTST (High Temperature – Short Time) sterilization or Flash Pasteurization: The product is heated to 72°C for about 20 seconds, then cooled and packaged.

- Tunnel Pasteurization: Often used in the retort process. After filling, the product can will be passed through a steam tunnel and heated to about 60°C for 8 minutes.

- Retort Pasteurization: Using a retort machine to sterilize beverage cans in a high-pressure environment. This is a common method for canned beverages.

- High Pressure Pasteurization (HPP): Using extremely high pressure to break down harmful microbial cells without heat, helping to preserve flavor and nutrition better.

- Labeling and packaging

The final step is like "makeup" for the product. This is the stage where the label and brand design are applied to the product.

There are many types of labels used for soft drinks, including: thermal transfer labels, heat shrink plastic labels, paper labels or sticker labels. In the past, labels were often applied manually, but with modern technology, automatic labeling machines have replaced the manual method, helping to increase accuracy and reduce errors.

After labeling, the product will be packaged according to the required quantity, put into cartons and transported to retail stores for distribution to the market.

Machinery in the beverage production line

Each process in the beverage production line will have different machinery. Below is an overview of the most common types of machinery in a beverage factory.

| General System | Clean-in-Place (CiP) System | A system of pumps and cleaners, the purpose of which is to clean all pumps and pipes without disassembling the machinery |

| Conveyors | Conveyors are used throughout the plant to transport products between stages | |

| Steamers | Used to generate hot steam for many processes (sterilization, labeling, etc.) | |

| Water Treatment | Membrane Filters | Remove large particles and contaminants |

| Carbon Filters | Remove smaller particles and kill bacteria | |

| RO Filters | Remove all smaller particles of contaminants, bacteria and toxic chemicals | |

| Mixing System | Mixing Tanks | Used to heat liquids, pasteurize and dissolve ingredients such as sugar |

| High Shear Mixers | Mix ingredients into smaller sizes | |

| Sterilizers | Distillers | Used to cooking and pasteurizing canned beverages after canning |

| Tunnel Sterilizer | It moves packaged beverage products through a hot steam tunnel to sterilize them | |

| HTST/UHT Sterilizer | These machines heat liquids, sterilizing them at high temperatures before filling | |

| Foaming Machine | Inject liquid CO2 into liquids, used for carbonated beverages | |

| Bottling | Bottle Filling Machine | Uses a pump system and different sized nozzles to fill beverage bottles |

| Capping Machine | Covering the bottle to seal the bottle | |

| Canning | Can Filling Machine | Uses a pump system to fill beverage cans |

| Packaging Machine | Covering the can and sealing the lid to the top of the beverage can. | |

| Aseptic Filling | Aseptic Filling Machine | A sterilizing and filling system installed in a closed, sterile space to create a sterile environment |

| Packaging System | Labeling Machine | Applying labels to beverage packaging. The most common type is the shrink labeling machine |

| Steaming Labeling Machine | Used to steam shrink labels, to make it wrap around and fit the packaging | |

| Plastic Packaging | Mixing drinks into packages, then coating them with a layer of plastic to bond them | |

| Canning Machine | Packing beverage packages into trays/cardboard boxes |

Automatic Conveyor Solutions in Beverage Production Lines

Conveyors are an indispensable component in beverage production lines, helping to automate the process of transporting bottles, cans, or product cartons through stages such as filling, capping, labeling, and packaging.

Below are common types of conveyors, their roles and specific applications in the beverage production line, explained in an easy-to-understand way:

- Plastic chain conveyor:

Made from high-quality plastic, light, durable, corrosion-resistant, and easy to clean. Plastic chain conveyors can be flexibly designed in straight lines, curves (30°, 45°, 90°), or spirals to suit the factory space.

Applied to transport PET bottles, glass bottles, or aluminum cans through the filling, capping, and labeling stages. Specific example: In the production line of Suntory PepsiCo Vietnam, plastic chain conveyors are used to transport 500ml Pepsi bottles from the filling area to the labeling machine at a speed of 50 bottles/minute.

With plastic chain conveyors, they will meet food hygiene standards, operate flexibly, and require little maintenance.

- Roller conveyor:

Consists of steel or plastic rollers, with good load-bearing capacity, transporting products from light (single bottles) to heavy (cartons). Roller conveyors are often integrated with motors or operated by gravity (slope).

This type of roller conveyor is used to move beverage crates (24 bottles/crate) from the packaging area to the storage warehouse, or transport PET bottles in the final stages. This type of conveyor has good load-bearing capacity, is energy-saving, and is suitable for large-scale production lines.

- Stainless steel chain conveyor:

Stainless steel chain conveyor is a specialized conveyor, widely used in beverage production lines thanks to its load-bearing capacity, corrosion resistance, and meets food hygiene and safety standards. This type of conveyor helps transport bottles, cans, or product crates through stages such as filling, capping, labeling, and packaging effectively.

Consists of stainless steel links linked together, combined with a sturdy support frame, drive motor, and speed control system. Can be transported in straight lines, curves (angles of 30°, 45°, 90°), or up/down slopes, suitable for many factory spaces.

Stainless steel chain conveyor helps to transport continuously during the bottling process, meeting large output

Conclusion

The beverage production line not only helps to increase productivity but also ensures consistent quality for each product. Choosing the right technology and equipment will help businesses optimize costs, meet market demand and improve competitiveness.

If you are looking for a modern and efficient production solution, do not forget to invest in a quality chain system for sustainable development in the beverage industry.