Mục lục

Roller conveyors are indispensable equipment in some factory operations, helping to transport goods quickly and flexibly. This type of conveyor has many different shapes: curved, straight, inclined, and they are also designed in a spiral shape for the need to transport goods up high.

What is a spiral roller conveyor?

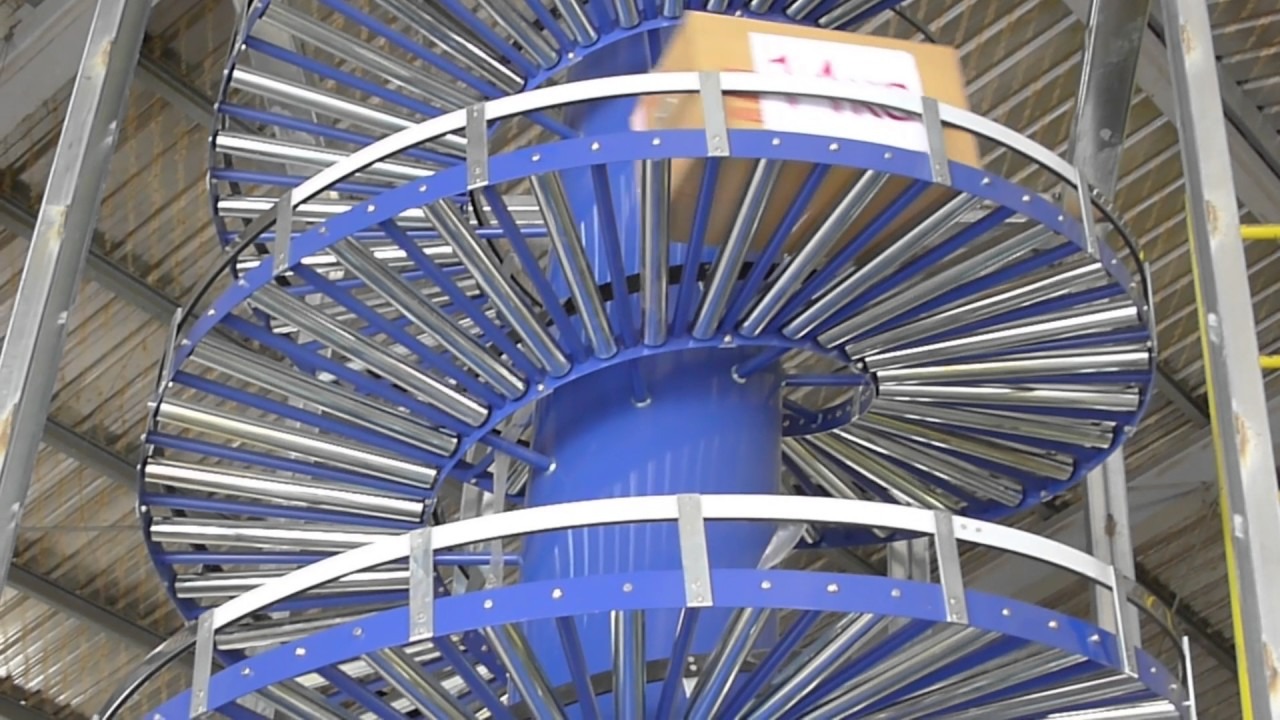

A spiral roller conveyor is a transport device designed in a spiral shape, allowing goods to move on rollers between different levels safely and efficiently. Typically, the roller conveyor will wrap around the central column to form a spiral with a gradual slope to make product handling easy.

Outstanding features of spiral roller conveyors

Roller conveyors include mechanisms and force effects by motors similar to chain conveyors or electric roller mechanisms.

- The conveyor uses a control motor so it can control the loading speed to reduce the product's movement too quickly, leading to product damage.

- In terms of structure, the design of the spiral conveyor requires high technical calculation. The tilt of the conveyor is designed according to the transportation requirements.

- Because the height of the rollers is not the same and is not flat on one side, the connection between the rollers with the sprocket chain structure will be very difficult to be accurate.

- Therefore, the spiral roller conveyor will be very difficult and risky for new conveyor units (you should choose reputable units with experience in conveyors to advise on ideas when customers have a need for a spiral conveyor structure).

- The solution of using electric rollers in the spiral conveyor is great. Because it can adjust the speed of each electric roller together or the entire roller conveyor system running at what speed. But it also has weaknesses like the sprocket chain roller type. With electric rollers, rubber belts will be used and moved by V or round pulleys.

- Electric rollers will be more optimal for units with high standards and willing to invest because the price of electric rollers is not cheap at all and there is no electric roller manufacturer in Vietnam, so it depends a lot on foreign manufacturers.

- With electric rollers, the price segment is mid-range and is used quite a lot by partners, plus the quality is quite good with the KYOWA electric roller line, of which Intech is a strategic partner in Vietnam.

Characteristics of gravity spiral roller conveyors

- The main difference between gravity spiral roller conveyors and other spiral conveyors is that this conveyor moves the load without using a motor source.

- Consists of free rollers joined together to move the product by translating the height of the front and rear rollers.

- Even though the structure of each roller has different height and angle, it does not affect much for free rollers because each roller will rotate freely when force is applied.

Benefits of using spiral roller conveyors

- Low power consumption

For gravity spiral roller conveyors, the products slide down smoothly through the rollers and make the transportation process perfect. No power consumption, this is the most environmentally friendly solution.

- Flexible customization

Spiral conveyors are the best solution for areas that require goods to be transferred to high places, between working floors. Conveyor sizes can be added to improve throughput.

- Low maintenance

Due to the simple structure of the frame, only simple and regular maintenance work is required. This saves a lot of labor costs and downtime.

- Save distance

The spiral conveying solution will not waste space. The compact structure saves valuable space for your factory.

- Reliable load capacity

No matter whether it is a light or heavy duty application, cartons and other containers can be transported smoothly and easily by spiral roller conveyors.

Applications of spiral roller conveyors

Spiral roller conveyors are the perfect solution for transporting cartons, crates, plastic boxes and other rigid packaging items. High quality conveyor rollers are installed on the entire conveyor to help transport products smoothly without consuming electricity.

Spiral roller conveyors can be installed at elevated transfer locations, between working floors in production areas, warehouses. The food, pharmaceutical, component, and automotive packaging industries most commonly use spiral roller conveyors.

Where is the best place to buy spiral roller conveyors?

Intech Group's spiral conveyors are designed with our proven, reliable technology. In terms of technology and price, Intech has mastered the technology and quality, so we will ensure peace of mind for our partners. Our conveyors offer many features and benefits.

Intech Group is ready to advise you on which spiral conveyor option is suitable for your needs. Please contact Intech, this can be easily done through our website on the contact page.

For any questions, please contact Hotline: 0966 966 032 for 24/7 support