Mục lục

What is a ball bearing roller?

Ball bearing rollers are rollers that can be used in all working environments from normal environments to working environments with corrosive chemicals, dust, etc.

Ball bearing rollers are also known as multi-directional rollers, capable of transferring goods in many different directions in conveyor systems. They are lightweight so they can be made into compact conveyor frames, easily folded up or stretched out depending on the purpose of use

The ball roller conveyor, also known as the multi-directional conveyor, ball conveyor or ball transfer table, is an extension product for the roller conveyor, its function is very simple and smart, instead of moving goods in one direction, the items can move in any direction at the same level on the ball blocks with individual bearings

Ball conveyors are often used when there is a requirement to rotate or position the product manually, such as an assembly workstation or other similar operation that requires quick and easy product handling.

Structure of the ball roller:

- The ball roller consists of a steel ball surrounded by a steel support assembly, this support assembly is made to fix the ball by covering 2/3 of the steel ball and leaving only the top 1/3 exposed. Below it are many small steel balls of about 1mm.

- When force is applied to the ball bearing roller, this force will be dispersed in many directions:

+ To use the ball bearing roller in the best and most effective way, people often install 10 or more. Therefore, the force applied is dispersed to the ball bearing rollers in the same sliding assembly.

+ The force applied to the roller is greatly reduced when the roller rotates in the direction of movement of the object to be transported.

+ The force is greatly dispersed to the steel balls below, only a part of the force is applied to the support assembly.

+ The force applied to the roller is greatly reduced when the roller rotates in the direction of movement of the object to be transported.

+ The force is greatly dispersed to the steel balls below, only a part of the force is applied to the support assembly.

Classification of ball bearing rollers:

There are 3 types of ball bearing rollers commonly used today:

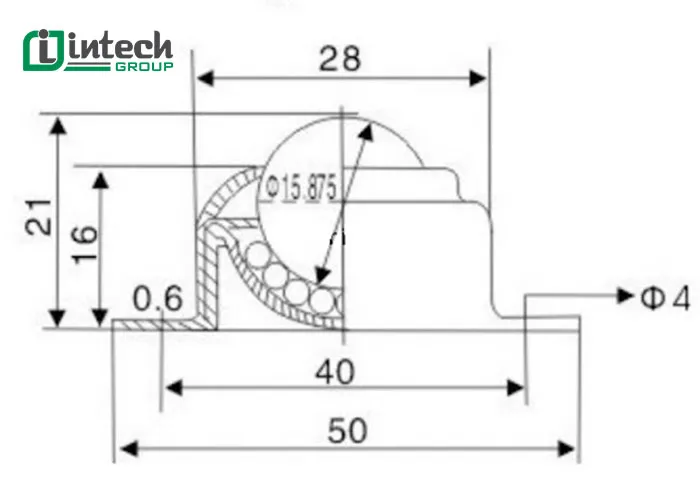

CY15 ball bearing roller:

- Material: High-strength steel.

- Main roller: 15mm steel ball.

- Load capacity: 10Kg.

- Height: 21mm.

- Outer support assembly length: 50mm.

- Distance between 2 hole centers: 40mm.

CY25 ball bearing roller:

- Material: Steel.

- Main roller: 25mm steel ball.

- Load capacity: 25Kg.

- Height: 30mm.

- Length of outer support cluster: 70mm.

- Distance between 2 hole centers: 55mm.

CY31 ball bearing roller:

- Material: Steel.

- Main roller: 30mm steel ball.

- Load capacity: 60Kg.

- Height: 40mm.

- Length of outer support cluster: 86mm.

- Distance between 2 hole centers: 70mm.

Advantages of ball bearing roller

- Flexible movement.

- Easy to install and use according to the requirements of each unit.

- Low cost.

- Ball bearing rollers are widely used in transmission systems, feeding, handling, processing machinery and packaging machinery auxiliary equipment.

- There are many types of ball bearing rollers on the market today, but the most popular are still CY15, CY25, CY31 ball bearing rollers.

Features of ball bearing rollers in multi-directional conveyors:

- Good load-bearing capacity, bearing weight from 5-300kg

- Carbon steel ball bearing, galvanized, stainless steel

- Hard ball cup

- The height of the ball table depends on the usage requirements, from 750mm - 12000mm

- Steel or stainless steel frame ball table

- The ball ball table can be designed in a curve

Benefits of using ball bearing roller conveyors:

- Ball bearing roller conveyors are the perfect connecting part at branches and intersections in the conveyor system with multi-directional configuration.

- Can be used to carry different heavy and light items easily

- They shorten the assembly and handling time.

- They adapt to the workplace optimally

- They help reduce transportation time and at the same time minimize the space required for the conveyor system.

- The load distribution is governed by the flatness, hardness, and smoothness of the load surface in contact with the balls. Allowing it to go around corners without problems.

Ball conveyors solve many material handling and motion control challenges. Conveyors make it easy to move or rotate light or heavy unit loads with a flat bottom. They enhance conveyor systems by allowing materials to move in multiple directions with minimal effort.