In industrial environments, rollers are subject to a lot of wear and tear. Therefore, steel rollers are often chosen because of their durability and cost-effectiveness compared to other materials. In addition, in many harsh working conditions, steel is also preferred over aluminum or plastic.

What is a steel roller? What is a zinc-plated steel roller?

Steel rollers and galvanized steel rollers are two types of rollers used in industrial applications. Both types of rollers play an important role in supporting and moving goods during transportation and circulation processes in the industry. The choice between steel rollers and galvanized steel rollers depends on the specific requirements of the application and working environment.

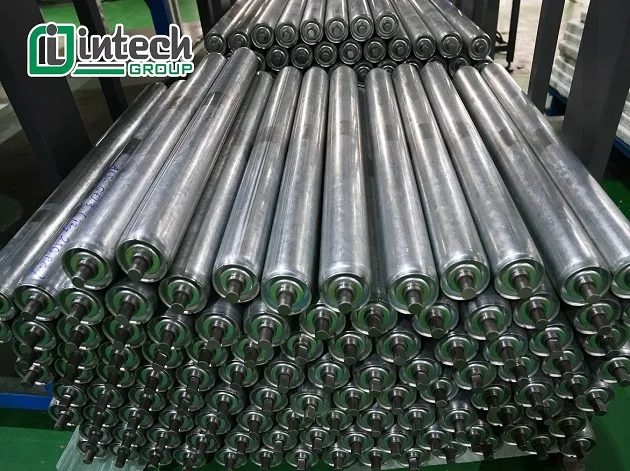

Steel rollers are usually made from special types of steel with high hardness, able to withstand large loads and impacts during operation. Steel rollers are usually cylindrical in shape, equipped with holes for its shaft so that it can be attached to equipment, machinery and moving systems.

Galvanized steel rollers are a type of steel roller that is coated with a zinc coating to resist corrosion and oxidation, which helps to prolong the life of the roller and reduce maintenance and repair costs. Galvanized steel rollers are often used in applications involving water or humid environments where there is a high risk of corrosion. It is often used in conveyor systems, transportation equipment and other industrial applications.

High quality steel roller processing

Outstanding features of galvanized steel rollers:

- Galvanized steel rollers are a type of roller processed and manufactured from galvanized steel pipes and shafts, with specialized bearings that retain oil and grease well, so the rollers are very durable when used

- In terms of size, they come in diameters of 32, 38, 42, 50, 60 and 76. In terms of length, we manufacture according to the size requested by customers, up to a length of 1500mm.

- With the light properties of steel, moving the roller is easy and convenient

- Galvanized steel rollers have high hardness and durability, and corrosion resistance helps protect against rust, increasing the life of the roller. In addition, galvanized rollers are highly aesthetic, shiny and look better than conventional steel rollers.

Applications of Steel Rollers and Galvanized Steel Rollers in Industrial Conveyor Systems

Steel rollers can be used in a variety of areas in conveyor technology. Steel conveyor rollers have a sturdy structure, smooth operation suitable for heavy loads.

Galvanized steel rollers can operate well in harsh environmental temperature conditions. Suitable for handling hard flat bottom loads such as cartons or pallets in electric or gravity roller conveyor systems

Steel roller conveyor systems move goods from one place to another, reducing the effort of moving loads in warehousing, package handling, manufacturing and distribution tasks. From handling light and small packaged products to food processing areas that require frequent washing, increasing production capacity and efficiency.

Steel rollers are also seen in crushers because the density and strength of steel is useful in crushing ores, grains, plastics and softer rocks. A more exotic use of steel rollers can be found in engraving presses, where they are used in conjunction with plates to press the printing plate onto paper.

Application of Galvanized Steel Rollers in Conveyor Systems

Comparison of Steel Rollers and Galvanized Steel Rollers

Both galvanized steel rollers and non-galvanized steel rollers are used in steel manufacturing industries, but there are certain differences:

- Corrosion protection: The zinc coating protects the galvanized steel rollers from corrosion, increasing the durability and longevity of the product, whereas non-galvanized steel rollers are more susceptible to corrosion and require regular maintenance.

- Aesthetics: Galvanized steel rollers are shiny and look better than non-galvanized steel rollers. They are often used in outdoor applications or in places where aesthetics are required.

- Hardness and durability: Galvanized steel rollers have better hardness and durability than non-galvanized steel rollers. This means it can withstand higher impact forces and abrasion.

- Cost: Galvanized steel rollers are often more expensive than non-galvanized steel rollers because the galvanizing process increases manufacturing costs. However, the increased durability and longevity can save on maintenance and replacement costs in the future.

In summary, galvanized steel rollers and non-galvanized steel rollers have their own advantages. However, in applications that require aesthetics and high durability, galvanized steel rollers are often preferred.

How to choose the best Steel Roller for your application

There are many important factors to consider when deciding on steel rollers, plastic rollers, or stainless steel rollers for your conveyor system. These include what materials are being handled, the environment in which your conveyor system operates, the size of your operation, cost, and more.

- Material Conveyed

The material your conveyor system conveys plays a major factor in deciding which type of roller you should use, steel, stainless steel, or plastic. If the material is heavy and large in size, steel or stainless steel rollers do a better job of withstanding their weight and impact forces. Plastic rollers are better suited for lighter weight materials because they have less stiffness.

However, corrosive materials can cause steel rollers to wear and tear slightly. Stainless steel or plastic rollers are an alternative to steel because they are corrosion resistant.

- Operating Environment

High temperature environments can also be detrimental to plastic rollers. Steel and stainless steel rollers can withstand extremely high temperatures, both in terms of the operating environment as well as the temperature of the material being conveyed.

Compared to steel, plastic has a greater degree of thermal expansion when exposed to high temperatures. When using plastic rollers, the operating temperature must be carefully considered or you may risk roller failure due to warping.

- Scale of Operation

For plastic conveyor rollers, due to their limited durability and strength, they may be more suitable for smaller conveyor operations such as those in food manufacturing industries. However, many food manufacturing industries now opt for stainless steel or steel rollers over plastic rollers because of their food grade standards and also because they are non-corrosive and easy to clean.

Larger operations, such as those in the mining industry, will do better with steel rollers due to their generally larger size, higher capacity, and long-lasting durability.

- Cost

Steel rollers are, in most cases, cheaper to manufacture than plastic rollers. Steel rollers have been the standard in the mining industry for many years and are manufactured economically.

Industrial rollers come in a variety of types, styles, sizes, and configurations. Here's how to make an informed decision when selecting rollers for your conveyor system. They help you make the right choice to increase profits, reduce costs, and reduce downtime.

Effective maintenance guide for Steel Rollers and Galvanized Steel Rollers

To maintain and care for steel rollers, you can take the following measures:

- Regular cleaning: Clean the steel rollers to remove dust, dirt, and grease from the surface. You can use a stiff brush or suitable detergent. Make sure to rinse and dry thoroughly after cleaning.

- Periodic inspection: Check the steel roller for corrosion, damage or deformation. Make sure that components such as bearings and shafts are still operating smoothly and without problems.

- Lubrication: Lubricate the steel roller to reduce friction and maintain performance. Use the grease or lubricant recommended by the manufacturer and follow the instructions for use.

- Adjustment: Make sure the steel roller is operating in a balanced and aligned condition. Check and adjust the roller positions and settings to ensure smooth and stable movement on the conveyor.

- Replacement and repair: When serious damage or broken rollers are found, they should be replaced or repaired immediately to avoid affecting the performance and safety of the system.

- Follow the instructions: Always follow the manufacturer's instructions for use and maintenance to ensure proper maintenance and care.

- Regular professional inspection and maintenance: Regular professional inspection and maintenance by experienced technicians to ensure stable and durable operation of steel rollers.

Current price quotes for steel rollers and galvanized steel rollers

Galvanized steel rollers are more expensive than regular steel rollers. Coating a layer of zinc on steel rollers increases production costs due to the galvanizing process and the use of additive materials. However, the price of galvanized steel rollers can also vary depending on many factors such as size, material, quality, quantity.

The choice between steel rollers and galvanized steel rollers depends on the specific requirements of the application and the working environment. If your application requires a better corrosion-resistant coating and protection for the steel roller, galvanized steel rollers may be a good choice despite the higher price.

The price of steel rollers will depend on the size of its length and diameter, the price is from 50,000 - 200,000 VND per 1 manufactured steel roller. For accurate information on the current price of steel rollers, you should contact the suppliers directly to get the most detailed and updated prices.

Address of reputable steel roller and galvanized steel roller manufacturing company

Intech Group is a leading supplier of steel rollers for industries in Vietnam and some neighboring countries. We manufacture rollers in all shapes, sizes, styles and colors to meet the needs of our customers and keep their processes running smoothly.

Intech's team of experts is dedicated to manufacturing and innovating its products. Therefore, our tailored custom solutions are perfected for customers in all industries. We provide quick and competitive quote responses. Intech's industrial steel rollers are designed to withstand the harshest conditions, such as temperature changes, high abrasives

Contact Intech Group for advice and the latest steel roller quotes:

- Hotline: 024 66 806 795

- Address: Lot 6, Lai Xa Industrial Cluster, Tay Tuu Ward, Hanoi City