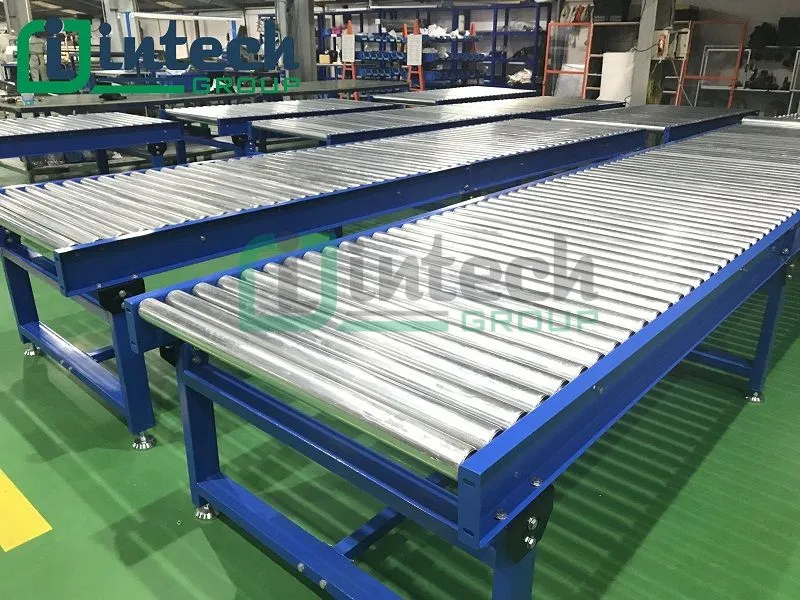

Industrial rollers are one of the most commonly used efficient equipment for transporting goods. They are often especially useful for packaging industries. For example, for transporting boxes and cartons through warehouses. They do not use energy, making them an efficient and popular transportation solution for material handling industries.

Rollers are the most economical and popular transportation option on the market. They are usually designed with a slight incline to take advantage of gravity and create product movement over long distances. Combining human push makes it easier to move products.

Outstanding features of industrial rollers:

Industrial rollers are usually made from steel rollers, stainless steel rollers, plastic rollers attached to a sturdy steel or aluminum frame.

- The free-rotating rollers allow products to move forward manually by pushing.

- Products can also roll on their own if the incline (slope) is adequate. Heavier products typically require less incline than lighter products.

- Industrial rollers are easy to remove and replace, allowing for quick and cost-effective maintenance.

Industrial roller rack specifications:

- Length: 1500 - 3000 mm and 45° 90° curves

- Frame width: 300, 450 and 600 mm (overall width)

- Height: 75, 115 or 150 mm.

- Roller length: 230, 390 and 540 mm

- Rollers on 1500 mm frames:

- Conveyor rollers are 50 mm in diameter and have spring-loaded axles that allow them to be easily mounted on the frame.

- Steel and stainless steel rollers can handle a total capacity of 110 kg each, while plastic rollers have a capacity of 50 kg each.

Benefits of using industrial roller conveyors

Roller conveyors offer many long-term benefits to your facility and workforce, such as:

- Simple and cost-effective design as they do not use electricity, moving products solely by gravity

- Roller conveyors can be installed in a variety of locations, with different specifications to suit a wide range of sizes and weights. This makes them practical for almost any warehouse application.

- The main benefit is the safe and simple efficient movement of materials.

- Requires fewer workers, forklifts and other machinery to move goods across the site.

- Combined with ease of operation and installation, gravity conveyors help reduce costs while optimizing your operations.

Different Applications for Industrial Rollers

The benefits of using industrial rollers can be applied to many industries with high production demands. Some of the activities that use industrial rollers include: Product assembly, Shipping, Order fulfillment

Rollers have been proven in countless daily warehouse operations allowing your employees to maximize their productivity. Areas where rollers are used include: warehouses, distribution centers, industrial manufacturing industries, etc.

Do you need an industrial roller system?

Industrial rollers do not require motors and are a quick and cost-effective solution for manufacturing and warehouse industries that need to move light to medium weight products around their facility. They provide a great way to optimize your warehouse in a flash.

With over 10 years of experience in the industrial sector, Intech Group will provide you with a quality, reliable roller system to serve all your production needs. Contact Intech today to learn more about our complete roller system product line, Hotline: 024 66 806 795