Plastic rollers are known to support movements in industrial equipment or for other industrial purposes. There are many types of plastic rollers that are widely used in factories, warehouses and many other fields, bringing many benefits.

What are plastic rollers?

Plastic rollers are an industrial product used in many industrial and civil applications, especially in conveyor systems and material handling equipment. With flexibility and diversity in size, shape and material, plastic rollers have become an indispensable solution to support the transportation, production and packaging processes.

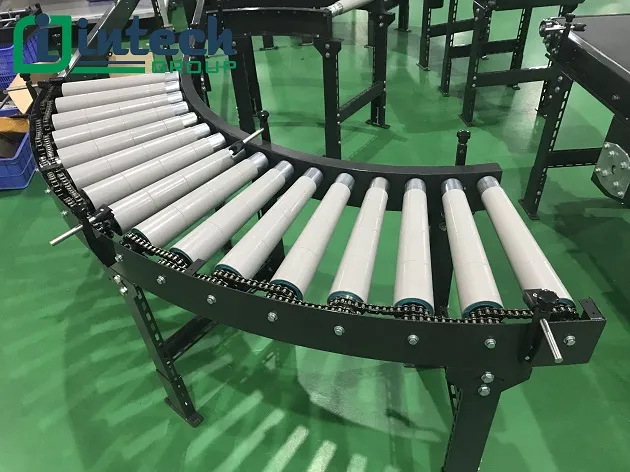

Plastic rollers are important parts in the conveyor system

Structural characteristics of plastic rollers:

Plastic rollers are one of the industrial roller products with a simple but extremely effective structure, including the following main parts:

- Roller shell: Made from plastics such as POM, PVC, PU, PP, HDPE, ... Has the function of protecting the parts inside the roller and bearing the load of goods. The advantages are high hardness, durability and good abrasion resistance.

- Roller shaft: Made of steel or aluminum, has high hardness and durability, good load bearing and is the main part that helps the roller rotate. Shaft machining requirements must be precise to ensure smooth rotation without shaking

- Roller bearing: Installed at both ends of the roller shaft, has the function of reducing friction and helping the roller rotate smoothly. Use ball bearings or sliding bearings made of steel or plastic.

- Roller seals: Installed at both ends of the roller shaft, made of rubber or plastic, with the function of preventing dirt and water from entering the bearing. Other parts: There are other parts such as: springs, gears, etc. depending on the function and purpose of use.

General specifications of plastic rollers:

- Size: Diameter 20, 25, 30, 40, 50, 60, 80, 100, 120, 150 mm

- Length: 100mm, 200mm, 300mm, 500mm, 1000mm (can be ordered upon request)

- Color: White, black (can be ordered upon request)

- Load capacity: 50kg

- Working temperature: -40°C to 100°C

- Friction coefficient: 0.2

Classification of plastic rollers

There are many ways to classify plastic rollers, based on different criteria:

1. Material:

- POM plastic roller: has a thick surface, yellow and white color, has high load capacity, good abrasion resistance, smooth operation, low price.

- PVC plastic roller: Good chemical resistance used in acidic or alkaline environments, low cost.

- PU plastic roller: High load capacity, good elasticity, good abrasion resistance, smooth operation, high cost.

- PP plastic roller: Light, good impact resistance, low cost.

- HDPE plastic roller: High load capacity, good chemical resistance, high cost.

2. Function:

- Guide roller: Helps the conveyor move in the right direction.

- Heavy duty roller: High load capacity, used for conveyors transporting heavy goods.

- Anti-static roller: Used for explosive environments.

Outstanding advantages of plastic rollers

Plastic rollers will be the best choice in terms of cost compared to stainless steel or steel rollers. In addition, it also has some other advantages such as:

- Simple structure: Including shaft, housing and bearing, making installation, use and maintenance easy.

- Light weight due to plastic, easy to move, install and maintain

- Made from high-strength plastics, withstand heavy loads, strong impacts and good abrasion.

- Good abrasion resistance. helps the roller operate smoothly, less wear.

- Smooth operation, low noise, helps protect the working environment.

- Easy to clean due to smooth surface, ensuring industrial hygiene standards

- Resistant to chemicals, water, suitable for use in humid environments.

- Does not contain toxic substances, safe for users, recyclable, environmentally friendly.

- Wide range of applications: Used in conveyor systems, industrial machinery, manufacturing, food processing, textile, printing, packaging, logistics, agriculture and construction.

Applications of plastic rollers

Plastic rollers are widely used in many different fields, including:

- Plastic rollers in conveyor systems:

Plastic conveyor rollers are the main part of the conveyor system, helping to transport goods from one point to another automatically, efficiently and cost-effectively. Plastic conveyor rollers are used for many different types of conveyors such as roller conveyors, gravity conveyors, inclined conveyors, etc.

Using plastic conveyor rollers helps reduce friction between goods and the conveyor surface, helping products move easily and save electricity. With flexible plastic materials, it will also help protect goods from scratches and damage during transportation.

Plastic rollers in conveyor systems help move goods safely

- In Industrial Machinery:

Plastic rollers are used for industrial machinery such as textile machines, printing machines, packaging machines, food processing machines, etc., playing an important role in transporting, transmitting and supporting other parts of the machinery to operate effectively.

- In industries

Used in manufacturing plants to transport raw materials, components, finished products, etc. Plastic rollers help improve production efficiency and save labor costs. Some industries that use plastic rollers:

- Food processing industry

- Textile industry

- Printing industry

- Packaging industry

- Logistics industry

- Agriculture industry

- Electronics industry

- Chemical industry

- Pharmaceutical industry

- Cosmetic industry

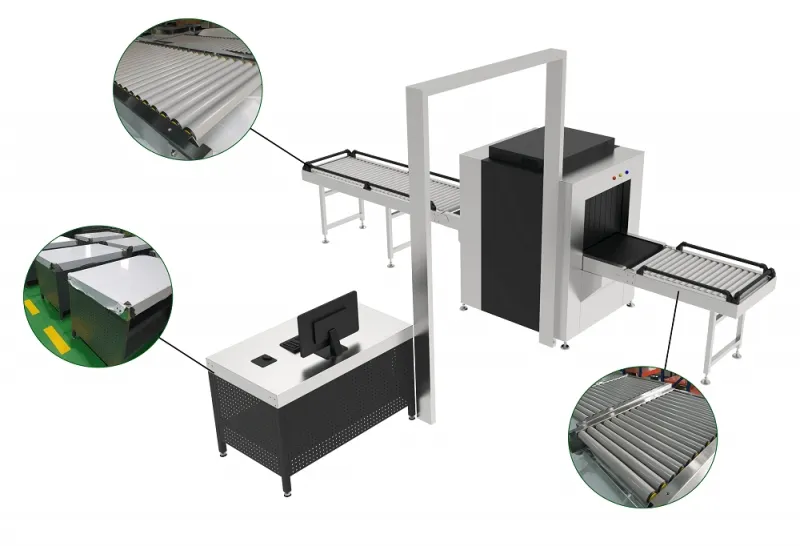

- Aviation industry

Plastic rollers in airport baggage conveyor roller systems

How to choose the right plastic conveyor roller

To determine the type of plastic conveyor roller that suits your needs, consider the following important factors:

1. Size:

- Choose the roller diameter that matches the width of the conveyor. You should choose a roller with a diameter about 10-20mm larger than the conveyor width to ensure stable transportation.

- The length of the roller depends on the size of the material to be transported. You should choose a roller with a length slightly longer than the size of the material to ensure safety.

2. Materials:

- ABS plastic has high durability, good impact resistance, suitable for harsh working environments.

- POM plastic has high load capacity, good abrasion resistance, suitable for transporting heavy materials.

- PVC plastic is cheap, light, easy to install, suitable for common applications.

3. Some other factors

- The shaft is made of steel, stainless steel with good load capacity, high durability

- Bearings have good load capacity, reduce noise

- Heat resistance is suitable for working environment

- Reputable roller manufacturing brand

Instructions for proper use and maintenance of plastic rollers

You can contact the supplier for specific advice and instructions on how to use plastic rollers correctly to ensure the durability of the roller. Here are some good tips to help you:

- How to use plastic rollers correctly to increase durability:

- Install the roller in the correct position, ensuring accuracy and balance.

- Test the roller to check for smooth operation, no unusual noise.

- Adjust the speed and load to suit your needs.

- Clean the plastic surface of the roller periodically to ensure operating efficiency and longevity.

- How to preserve plastic rollers to increase their lifespan:

- Store in a dry, cool place, away from direct sunlight.

- Avoid storing at too high or too low temperatures.

- Avoid exposing plastic rollers to strong chemicals.

- Check the roller periodically to detect damage and repair promptly.

How much does a plastic roller cost?

The price of a plastic roller depends on many factors such as size, type of plastic material used, PP, PE or PVC. In addition, there are a number of other factors that also affect the price, such as large processing quantities, which will reduce the cost per roller. Roller manufacturing technology is also noted in the process of quoting plastic rollers.

Intech Group provides reputable plastic rollers at good prices

With outstanding advantages, plastic rollers are a smart, efficient and economical transportation solution for all businesses. Choose the right plastic roller to optimize operational efficiency and improve productivity for your work.

Intech Company is a designer and manufacturer of plastic rollers for industrial applications. Our rollers are made of high-quality plastic pipes, comply with strict quality standards, meet or exceed industry specifications for dimensional accuracy, load capacity and operational reliability.

Contact us now for advice and support in choosing the right plastic roller for your needs!

Contact to order:

- Address: Lot 6, Lai Xa Industrial Park, Tay Tuu Ward, Hanoi City

- Phone: 024 66 806 795

- Email: info@intech-group.vn